WORKNC is known for its powerful machining strategies, but one of its most underrated strengths lies in its Analysis tools.

These tools allow programmers and machinists to better understand part geometry, identify potential issues, and prepare data for toolpath generation. Among them, the Sections command stands out as a versatile feature for visualizing and analyzing cross-sections of complex parts.

Accessing the Sections Command

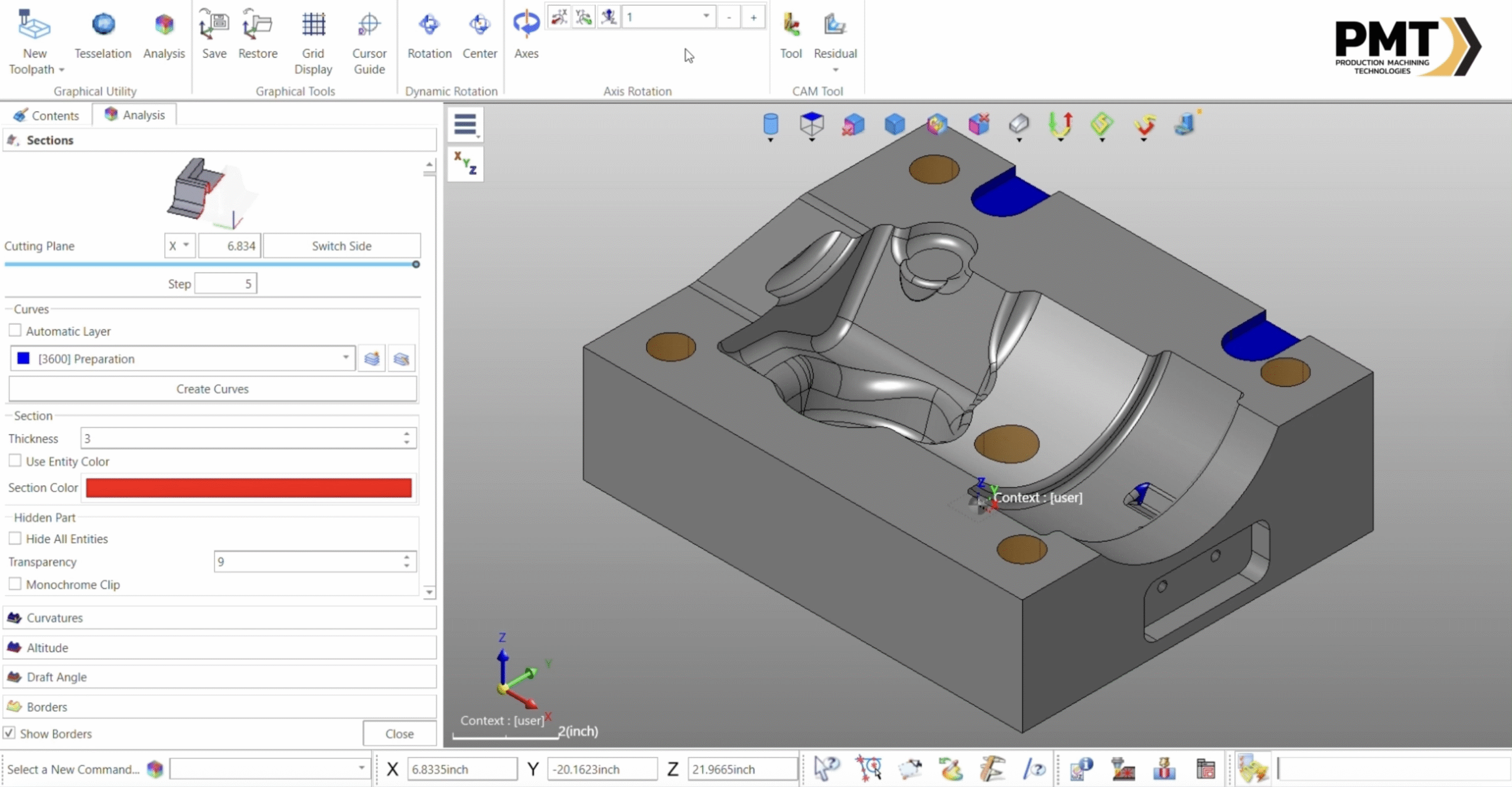

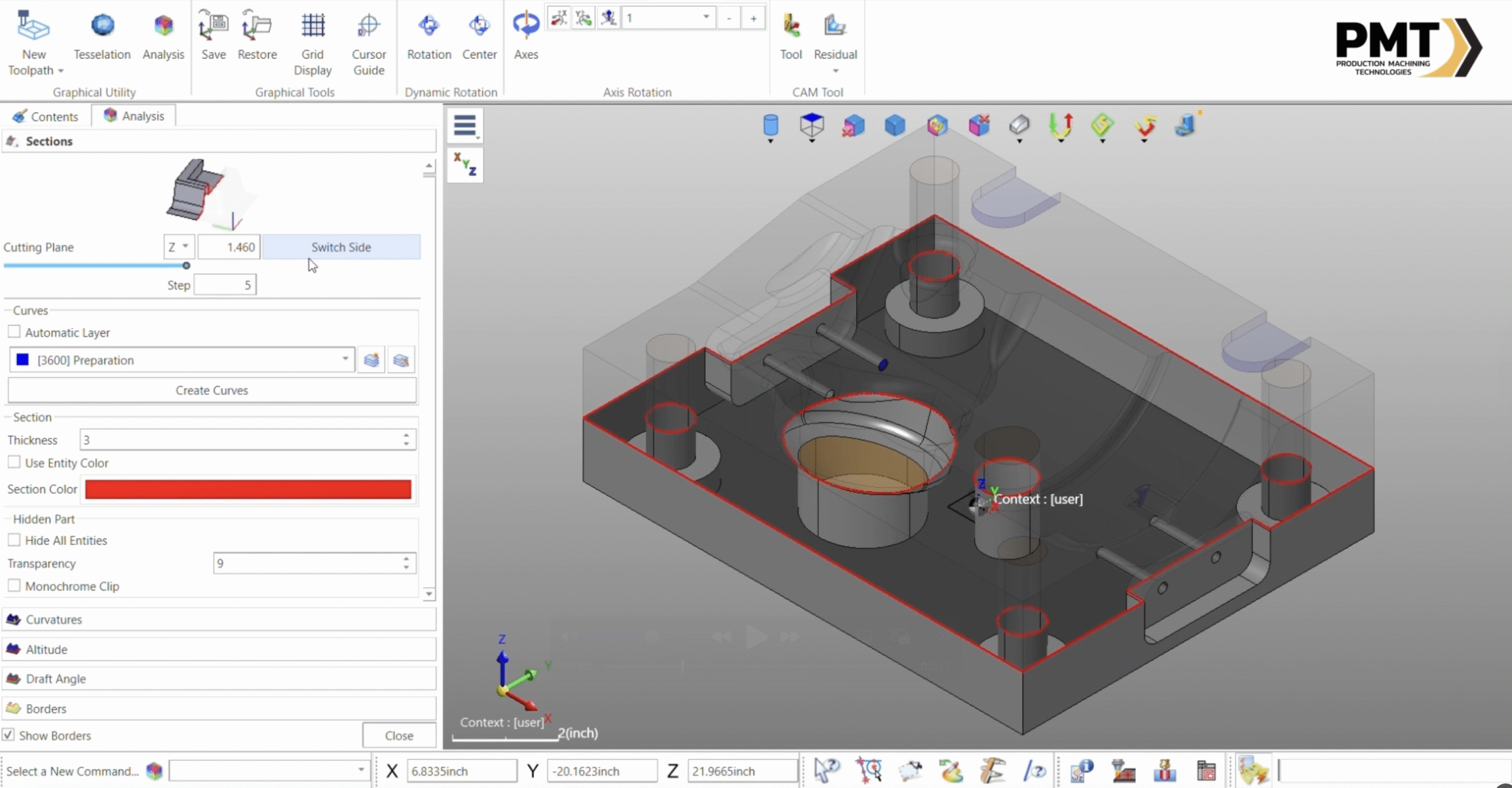

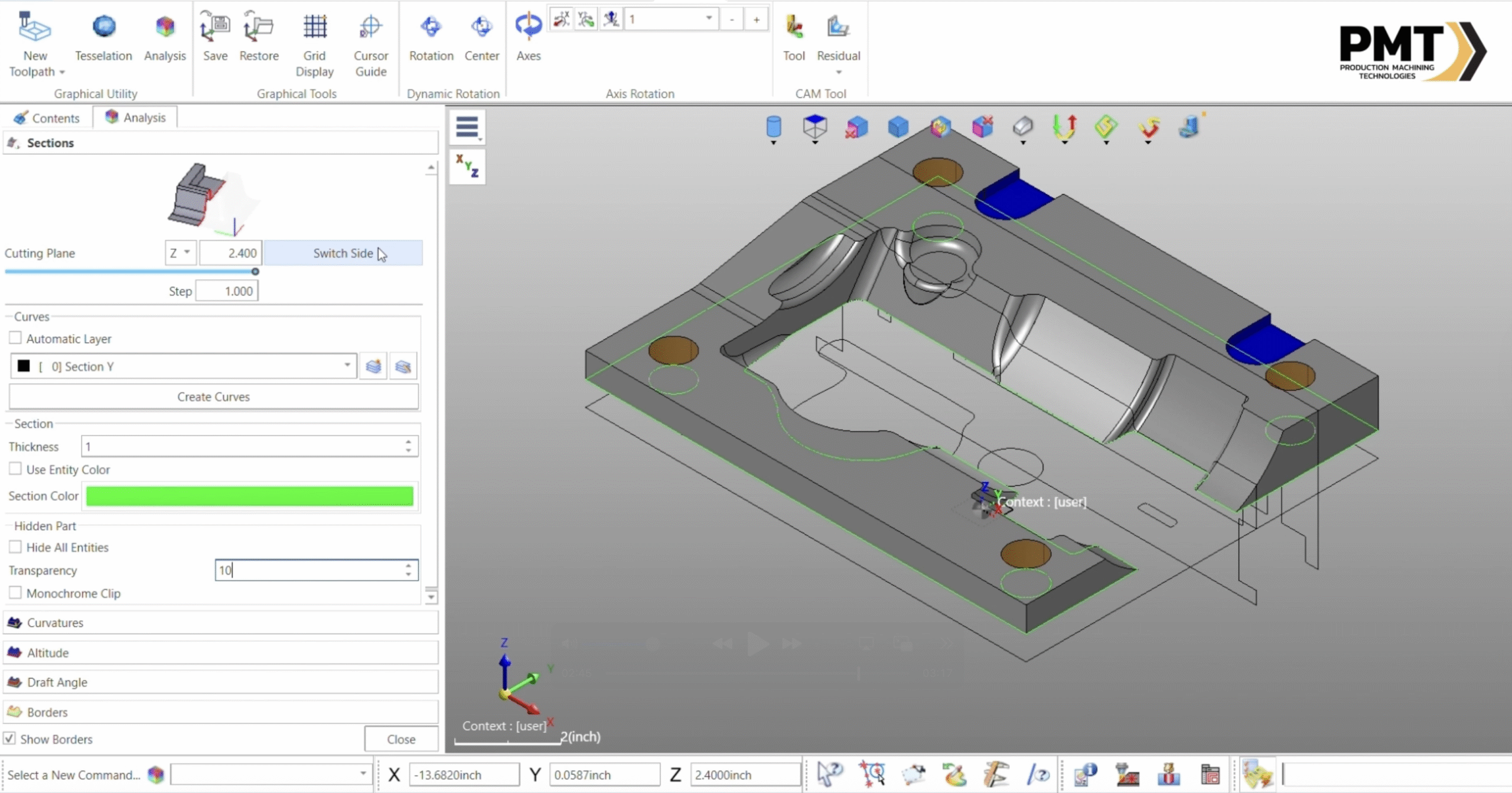

The Sections command is available directly from the Analysis menu. Once activated, it allows you to dynamically drag your cursor across the model to generate instant cross-sectional views.

Key options include:

- Switching between left or right side sectioning

- Selecting the sectioning axis (X, Y or Z) to toggle between top-down or bottom-up perspectives

For precise inspection, you can also enter exact values. For example:

- Typing Z = 2.0 in. provides a cross-section at exactly 2 inches in the Z direction

- Typing X = 0 quickly generates a centerline view

This makes it easy to evaluate internal features at specific locations without guesswork.

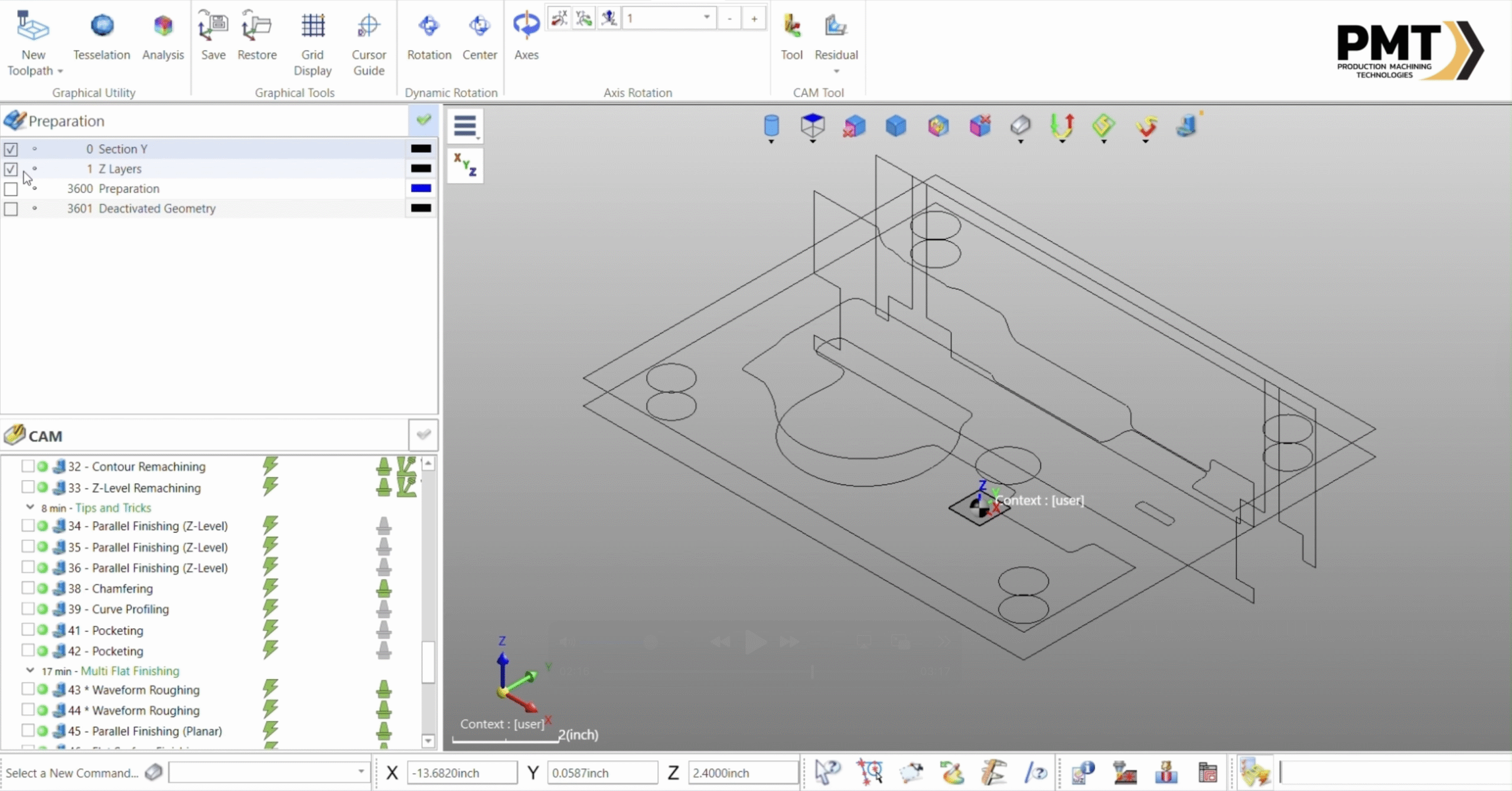

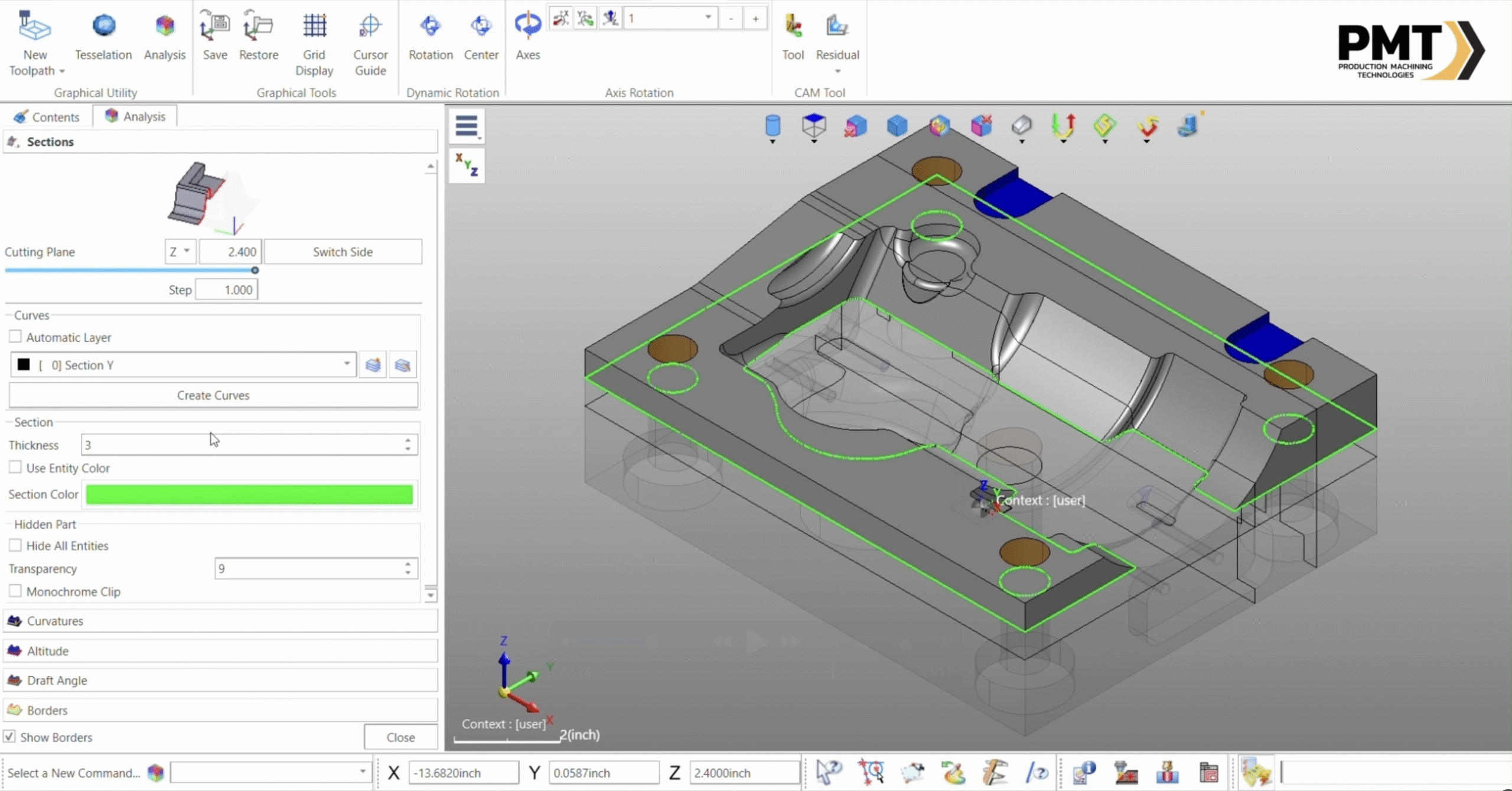

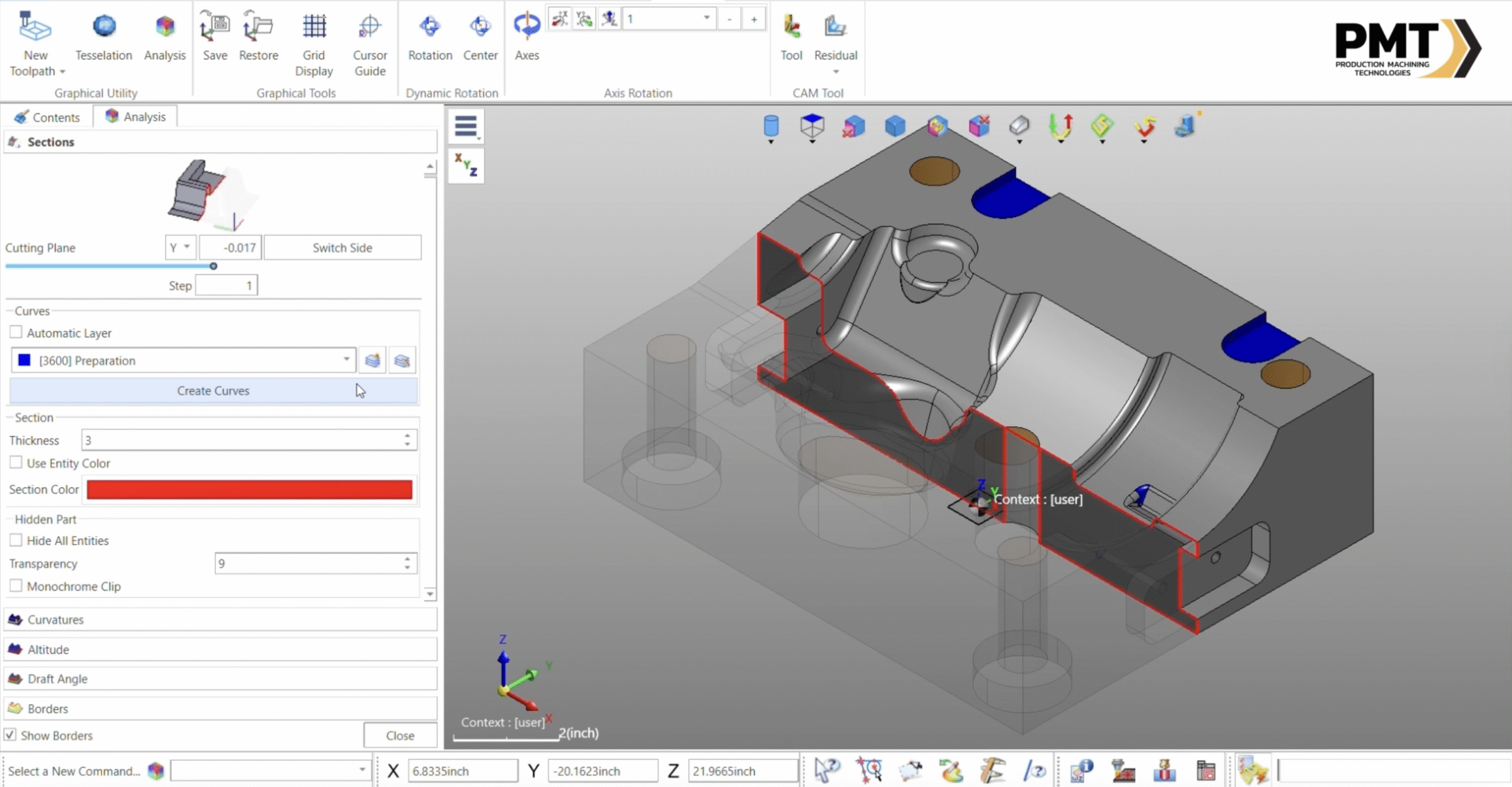

Creating Curves from Sections

Beyond visual inspection, the Sections tool supports direct curve creation. With a single click on Create Curves, you can instantly generate geometry from the section being viewed.

Additional options include:

- Position control: Select any location to generate curves

- Layer management: Store curves on a new, uniquely named layer (e.g., Section_Y)

Axis switching: Capture geometry from different perspectives for a more complete model

Once curves are created, they persist outside the Analysis mode and can be used in Preparation mode for downstream tasks such as machining or reference geometry.

Enhancing Visibility

The Sections command includes several visualization enhancements:

- Entity Color Control: Assign a different color to sectioned geometry for better contrast

Line Thickness Adjustment: Increase thickness to highlight cross-sections clearly

- Transparency Settings: Control the visibility of the non-sectioned half of the part

- 0 = fully visible

- 10 = completely transparent

Any value in between adjusts transparency for optimal clarity

These tools allow users to tailor the display for maximum readability, particularly when dealing with complex or crowded models.

Why This Matters

The Sections tool is more than just a visualization feature. It allows programmers to:

- Validate part geometry before machining

- Extract accurate cross-sectional data

- Prepare reference curves for toolpath creation

- Improve efficiency by reducing trial-and-error during toolpath programming

By incorporating this tool into your workflow, you gain a more precise understanding of your part, resulting in improved machining accuracy and reduced rework.

Conclusion

The Sections command in WorkNC Analysis is a powerful resource for anyone looking to gain deeper insights into part geometry. With its ability to dynamically generate cross-sections, create usable curves, and fine-tune visualization, it offers both flexibility and precision in preparing complex machining jobs.

If you’d like to explore this further or need assistance applying these techniques in your workflow, don’t hesitate to reach out.