WHY CHOOSE PMT?

EXPERT TRAINING:

Learn from our ESPRIT-certified trainers. On-site or virtually. Become an expert.

DEDICATED SUPPORT:

Get ongoing assistance for all your manufacturing challenges. We're here to help you.

CUSTOMIZED IMPLEMENTATION:

Ensure a smooth transition to ESPRIT with our tailored implementation strategies.

Maximize CNC Precision with Advanced Probing

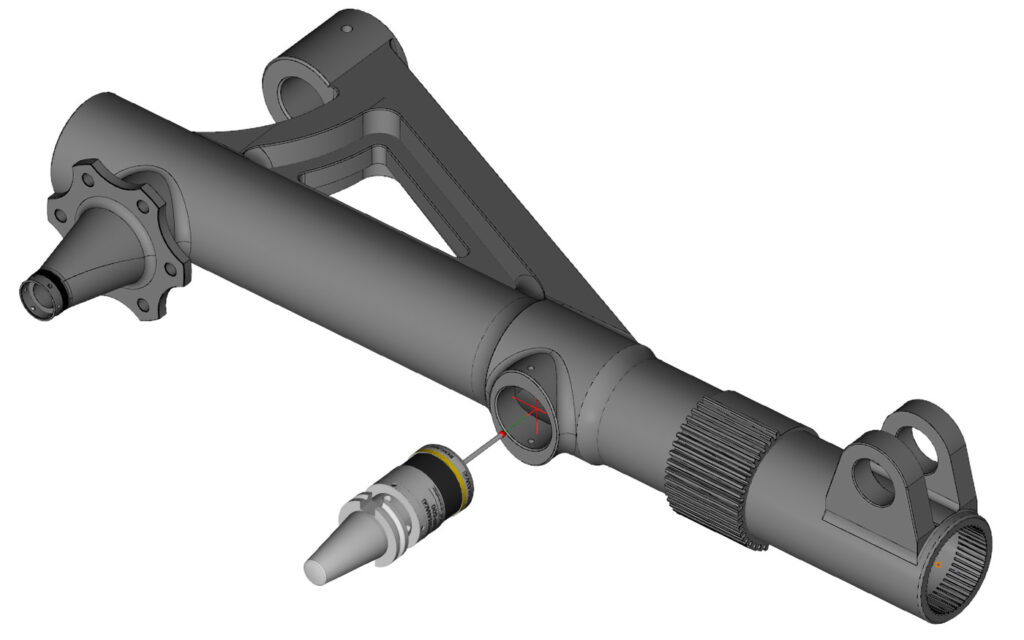

Misload Detection

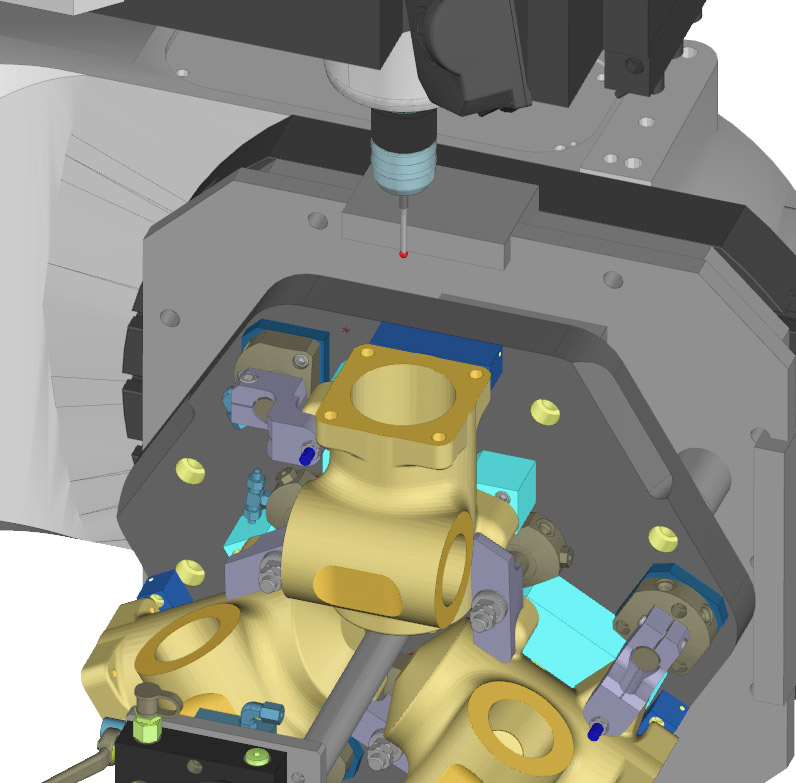

On-Machine Inspection

Enhance your machining accuracy with on-machine, in-process inspection that guarantees consistent and precise measurements, eliminating the risk of manual errors. ESPRIT's comprehensive suite of inspection routines is designed to work flawlessly across all types of CNC machines. Simply choose the geometry of the part you wish to measure, and the system intelligently selects the appropriate probing routine and settings for you. For complex 4- or 5-axis projects, ESPRIT's advanced 3+2 Probing cycles precisely adjust the part orientation using rotary axes, ensuring accurate measurements for multi-axis workpieces every time.

- Guarantees precise and consistent measurements

- Intelligent probing routine selection based on part geometry

- Reduces manual measurement inaccuracies

- Precise orientation and measurement of multi-axis workpieces

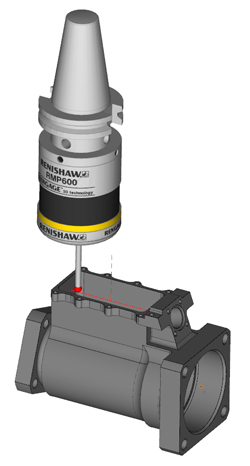

Dynamic Tool Offsets

Adapt dynamically to tool wear and ensure your critical part features are machined to exact tolerances. Our probing cycles measure remaining stock in real-time, allowing for automatic tool offset updates. This seamless adaptation ensures your machining process remains precise, even as conditions change, delivering unmatched accuracy in your final product.

- Seamlessly adapt to tool wear for precision machining

- Ensure exact tolerances for critical part features

- Dynamically update tool offsets based on real-time measurements

- Maintain precision throughout the machining process

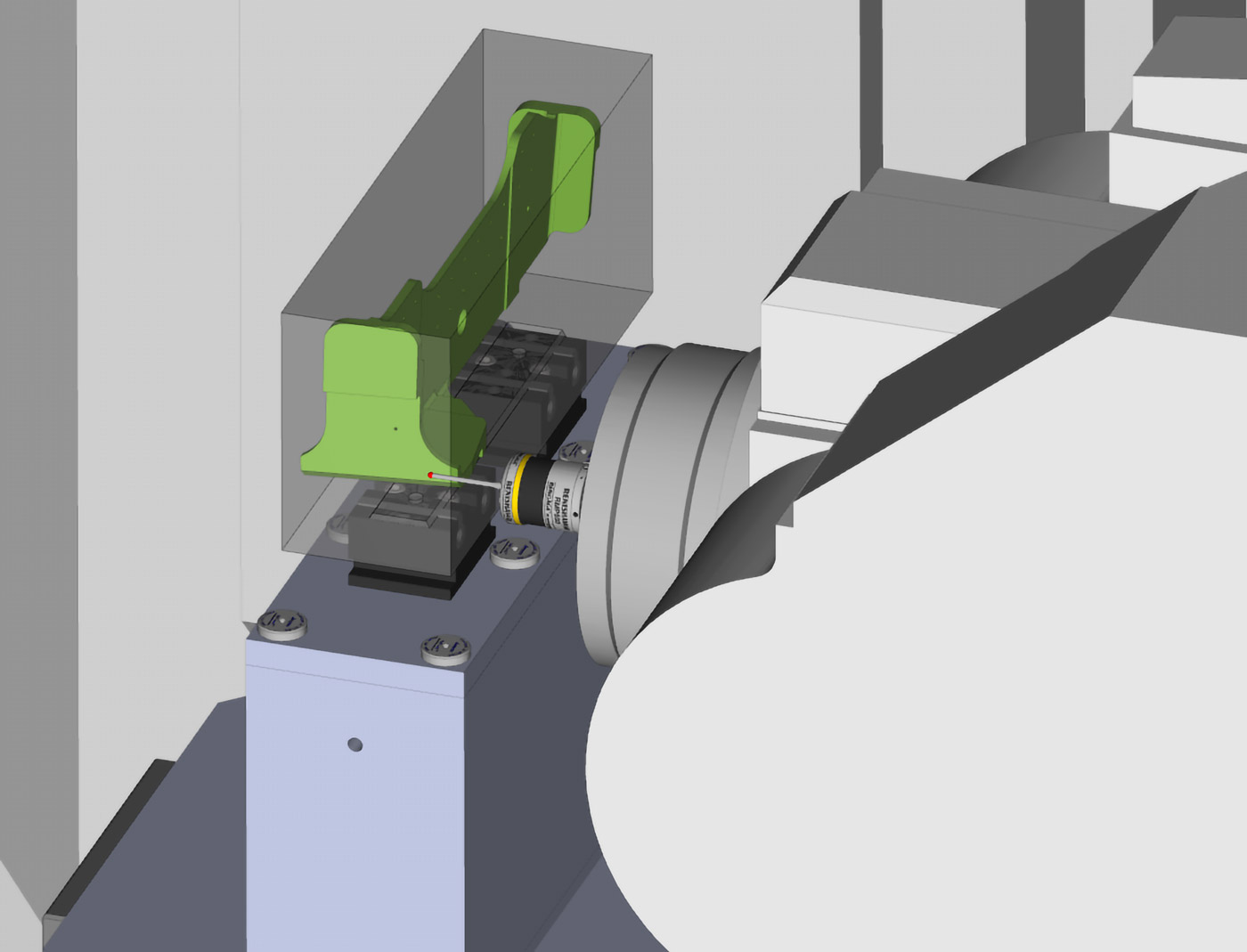

Machine-Aware Probing

Probing Features

Unlock the full potential of your CNC machine with our versatile 3+2 probing cycles, available at any point in the program. With advanced features like automatic cycle verification and probing pattern visualization, our solutions simplify complex processes. Supported probing cycles cater to a wide range of needs, ensuring precise measurements and superior machining performance.

- Versatile 3+2 probing cycles enhance CNC machine capabilities

- Simplify processes with automatic cycle verification

- Visualize probing patterns for accuracy

- Cater to diverse machining needs with a wide range of supported cycles