WHY CHOOSE PMT?

EXPERT TRAINING:

Learn from our ESPRIT-certified trainers. On-site or virtually. Become an expert.

DEDICATED SUPPORT:

Get ongoing assistance for all your manufacturing challenges. We're here to help you.

CUSTOMIZED IMPLEMENTATION:

Ensure a smooth transition to ESPRIT with our tailored implementation strategies.

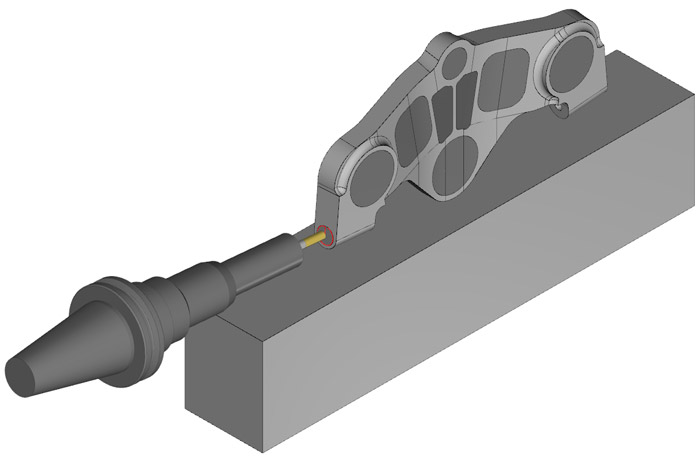

Elevate Your CNC Machining with ESPRIT SolidMill®

Enhance your CNC machining with ESPRIT SolidMill® via PM Technologies. This suite adapts to various machines, enabling quick, precise toolpath creation for any project. Minimize tool breakage risks and boost efficiency with smart stock calculations and optimized G-code. Achieve unparalleled precision and productivity, taking your machining quality to the next level.

Programming Automation

Adaptive Machining Cycles

Maximize your machine's capabilities with ESPRIT's SolidMill machining cycles, designed to adapt and optimize your machining strategy. Experience unparalleled control with cycles that offer rotary machining with polar interpolation, enhancing tool travel and efficiency. With a vast array of approach, entry, exit, and retract strategies, your tool is protected from shocks, ensuring longevity and flawless execution. ESPRIT's intelligent management of feedrates, clearances, offsets, and more ensures each cut is perfected for your specific needs.

Key Features:

- Rotary Machining with Polar Interpolation: For optimized tool travel and efficiency.

- Extensive Control Over Toolpath: Protect your tool with strategic entry, exit, and retract methods.

- Technical Parameter Management: Fine-tune feedrates, clearances, and offsets for perfect cuts.

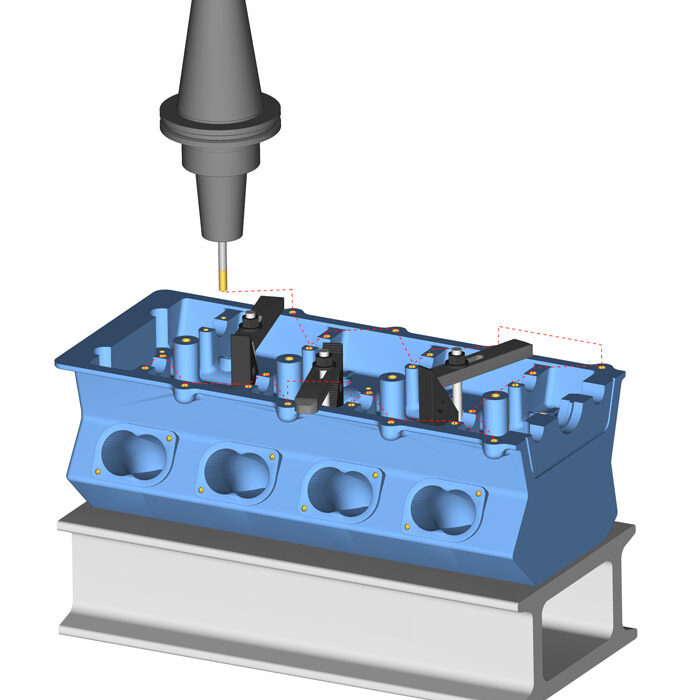

Holemaking

Master every holemaking challenge with ESPRIT's advanced cycles, capable of producing a diverse array of hole styles with optimized efficiency. Whether dealing with blind, through, interrupted, deep, threaded, countersink, or counterbore holes, ESPRIT offers the versatility to use a spinning tool, a spinning workpiece, or both. This suite ensures rapid production of toolpaths for any number of holes, delivering minimal cycle times without sacrificing precision.

Key Features:

- Diverse Hole Styles: Easily produce blind, through, interrupted, deep, threaded, and more hole types.

- Optimized Toolpaths: Achieve minimal cycle times for any number of holes.

- Flexible Tool and Workpiece Options: Use spinning tools, workpieces, or both for precision holemaking.

Facing & Roughing

Contouring & Finishing

Unlock the full potential of contouring and finishing with ESPRIT's flexible cutting cycle, ideal for a wide range of machining tasks. From removing material along vertical or tapered walls to crafting perfect chamfers, this operation ensures roughing and finishing are executed with precision. Automatic toolpath trimming to the remaining stock minimizes cycle times, optimizing your workflow for better results faster.

Key Features:

- Wide Machining Applications: Ideal for roughing and finishing of all shapes.

- Material Removal Optimization: Automatic toolpath adjustments to minimize cycle times.

- Stepover and Depth Precision: Multiple passes for perfect finish and form.