We’ve all been there, we set up our Freeform feature correctly, we dialed our tool in, we’ve even modeled in our exact tool holders.

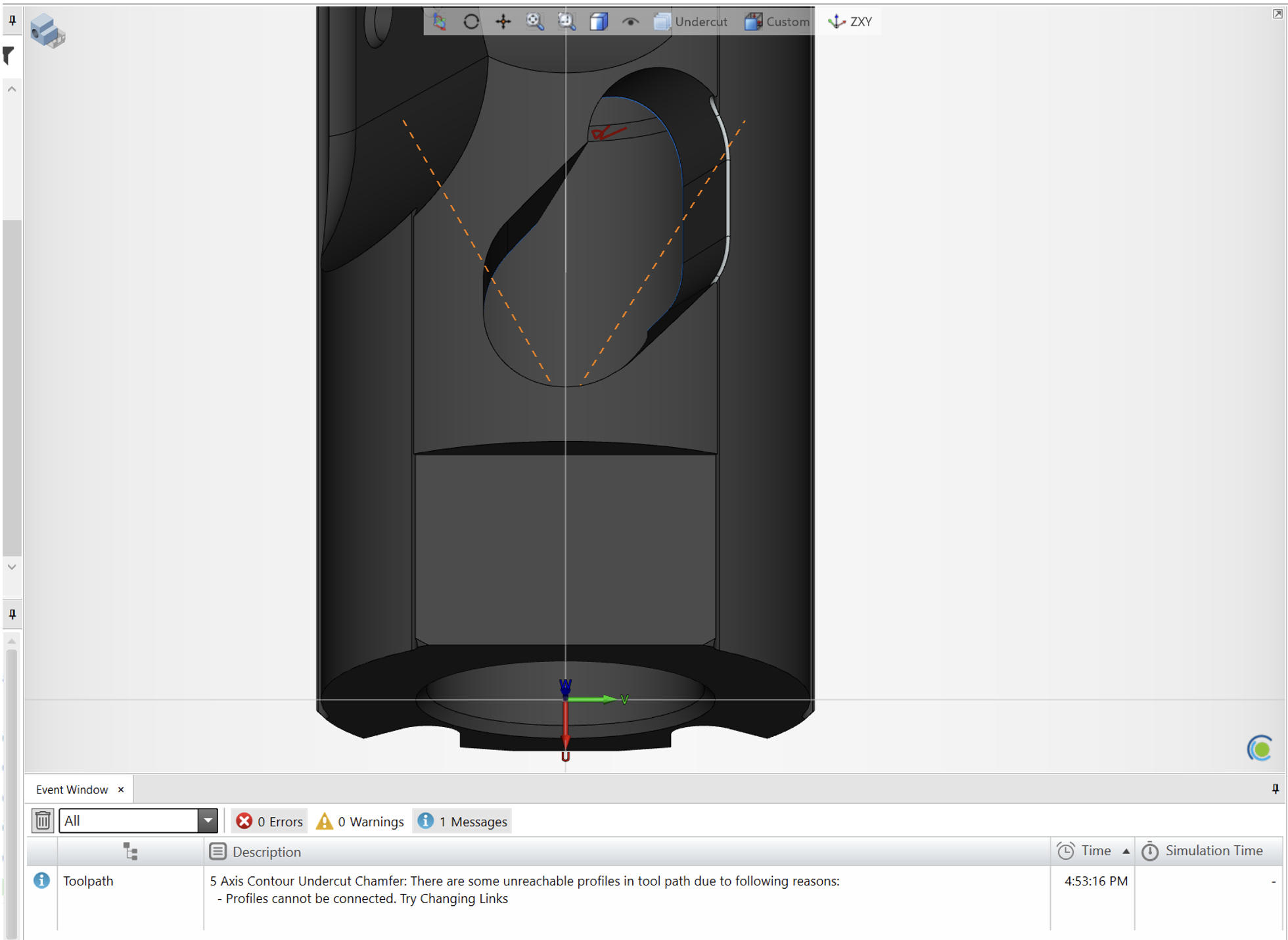

All just to have “Unreachable Profiles Error” show up on our screens after our first attempt at a 5 axis operation.

Don’t let this discourage you!. There is a setting that can be changed in ESPRIT to provide some clarity as to why there are unreachable profiles within the operation.

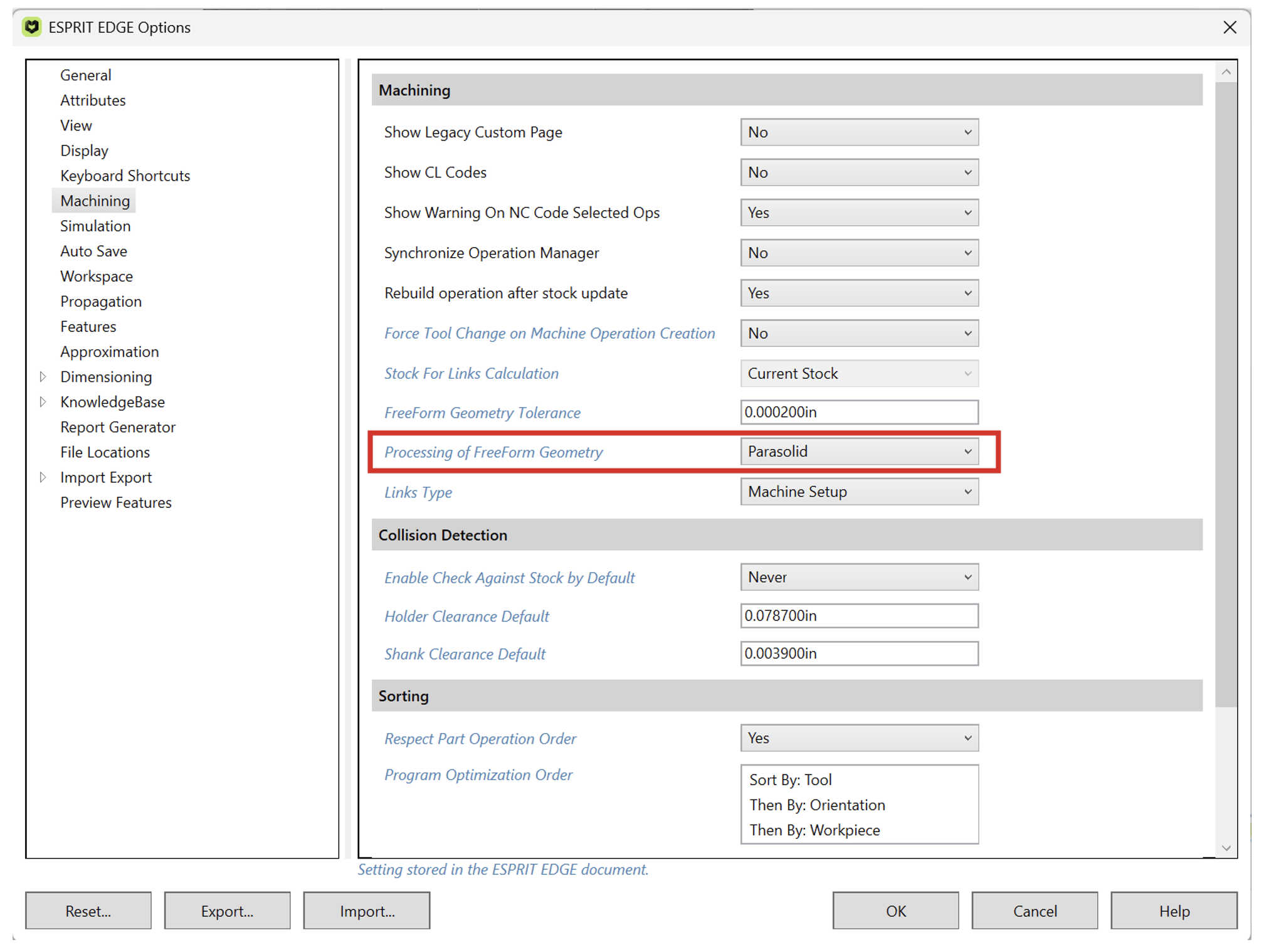

Navigating to File > Options > Machining tab,

We will change the Processing Of FreeForm Geometry field: from Paresolid – Target Part Caching > Parasolid.

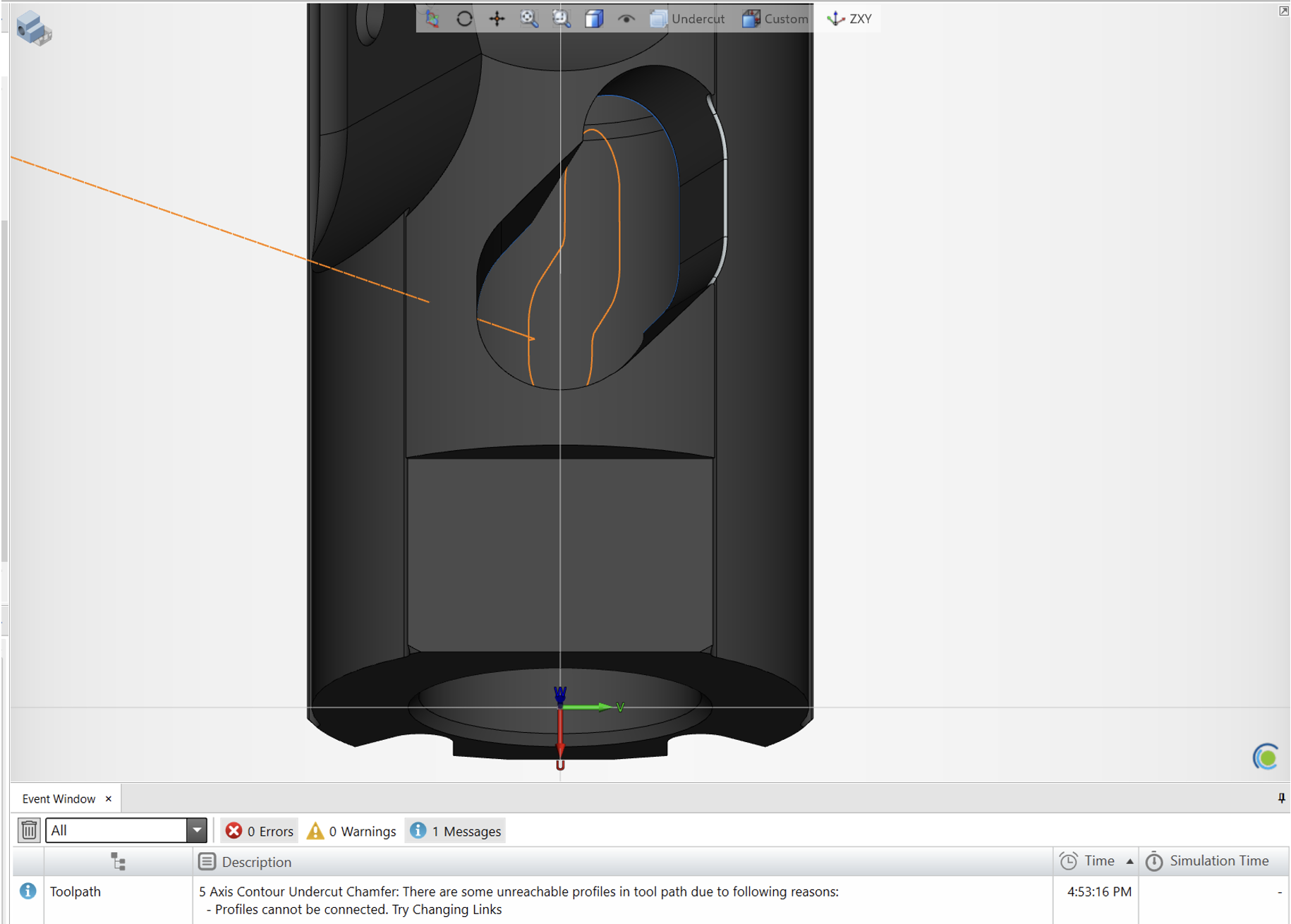

Rebuilding the operation will now provide us with a different picture. But Why?!

Parasolid – Target Part Caching will allow the operation to reference the target part model during calculation, regardless of the surfaces selected in the FreeForm feature. This is beneficial for a multitude of reasons, with the main benefit being the prevention of target part violation.

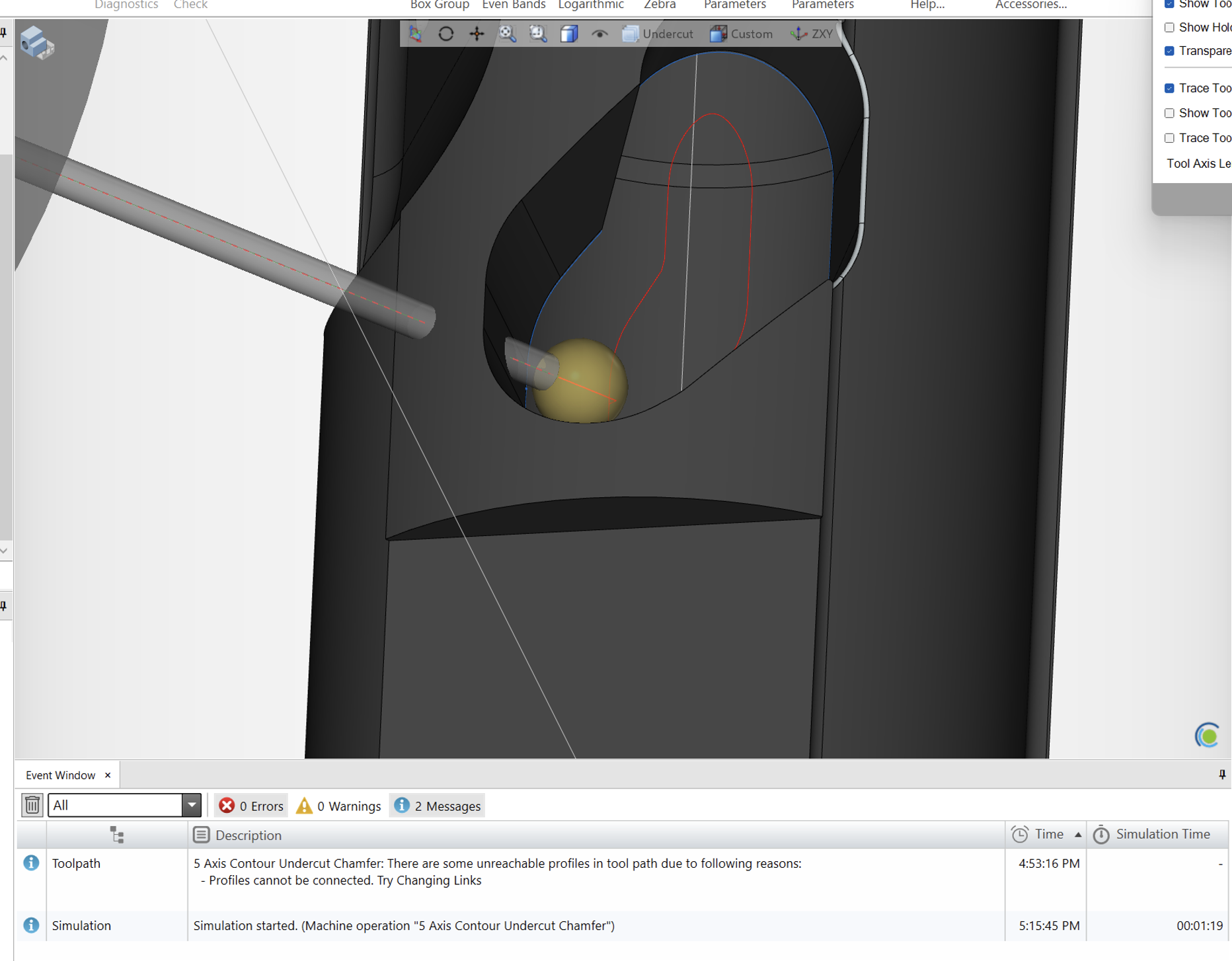

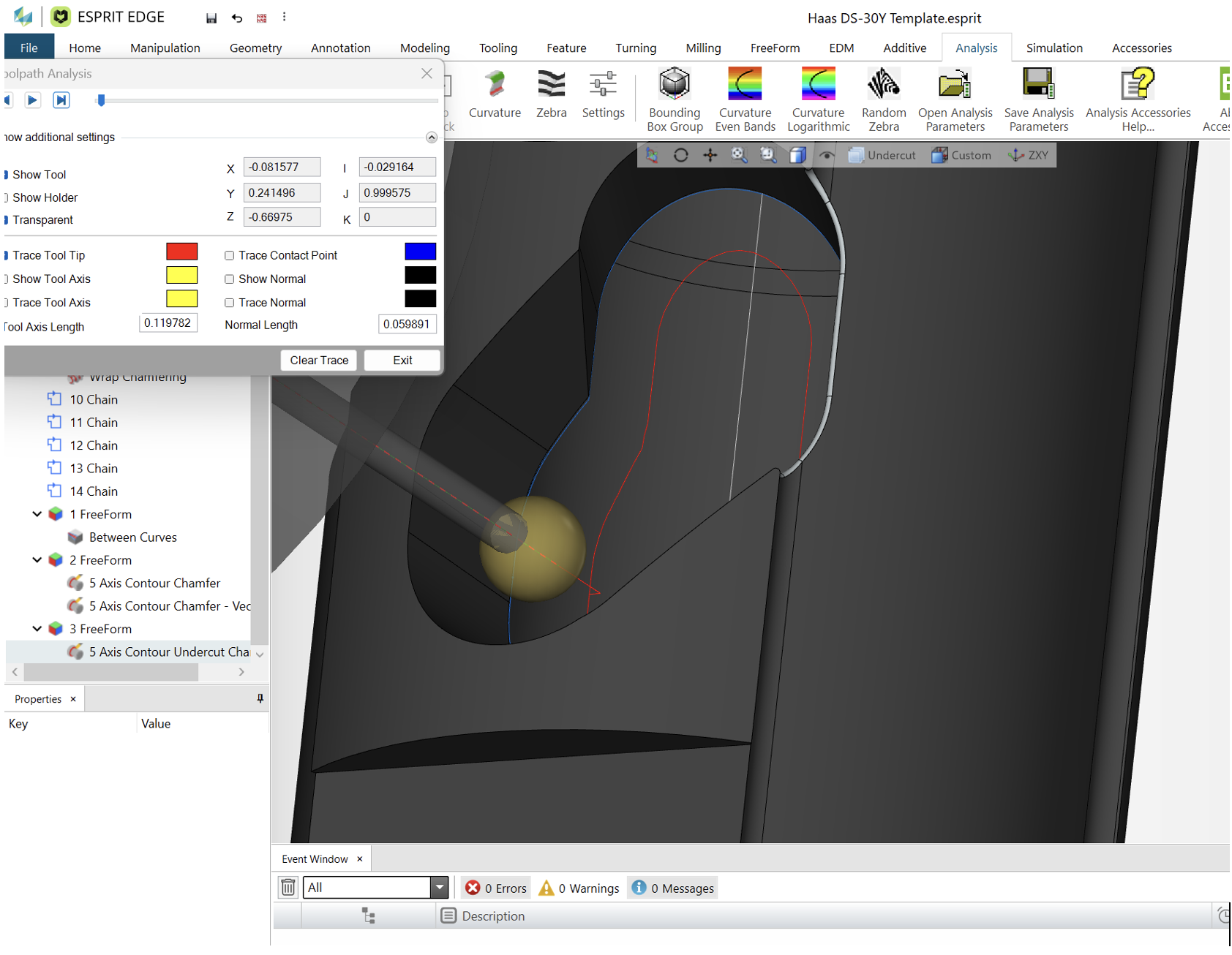

Toolpath Analysis shows us that we are entering through the side of the model which further explains our Entry/Exit move error. In this instance, it comes down to a tool-part orientation adjustment.

This is where knowledge of angle limitations and constraints will come into play. (not discussed here)

We all wish there was a magic wand that we could wave and have the perfect toolpath generated with every first attempt, unfortunately the magic wands are reserved for wire EDM.

However, with this simple change, even the most seasoned 5-axis veterans are sure to reduce their programming keystroke count.