ESPRIT EDGE 2025.4 is here, and this update is all about improving accuracy, toolpath quality, and day-to-day reliability. Instead of introducing big new features, this release strengthens the areas machinists use the most.

Below is a quick look at the improvements that matter on the shop floor.

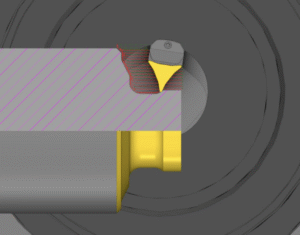

More Reliable Canned Cycles for Turning

Canned cycles are great when you want quick edits at the machine, but they haven’t always matched what you saw on-screen. With 2025.4, ESPRIT EDGE tightens that up.

What’s improved:

-

The approach point now matches the defined stock diameter

-

Start positions are consistent with the on-screen toolpath

-

Finish pass behavior lines up with what you programmed

-

ESPRIT now warns you when a canned cycle isn’t safe to use

What this means in real life:

You get canned cycles that behave more predictably, with fewer surprises and fewer edits at the control.

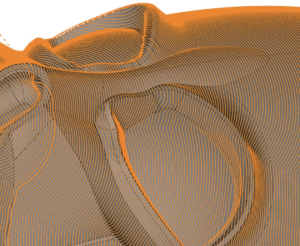

Cleaner 5-Axis Surfaces With New Toolpath Options

Composite got some solid upgrades that help with finish quality and toolpath smoothness.

Highlights:

-

True equidistant stepover for more consistent surfaces

-

New spiral toolpath option removes witness marks

-

Corner-rounding for smoother transitions

-

Drive Profiles now supports spiral + rounding too

Why shops will like it:

Parts come off the machine with cleaner finishes, especially molds, blades, and sculpted surfaces.

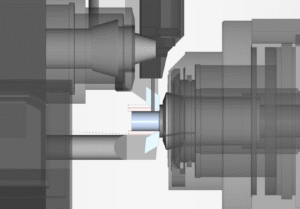

New 3-Axis Turning Roughing Strategy

For machines with a programmable tool spindle, there’s a new roughing strategy that automatically adjusts the insert orientation as it moves.

Benefits:

-

Keeps a constant lead angle

-

Improves chip flow

-

Avoids rubbing

-

Works with ProfitTurning

-

Supports Sandvik Y-tooling and Ceratizit FreeTurn

Why it matters:

You can rough complex profiles in one operation while extending tool life and reducing the chance of a collision.

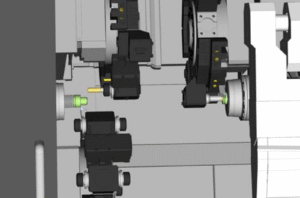

Safer, Smarter Swiss Programming

Swiss machines get several meaningful improvements that reduce risk and improve consistency.

Notable updates:

-

Balanced Turning now includes a “Preserve Tool Order” option

-

Prevents the trailing tool from colliding with the guide bushing

-

Smoother handling of stock retraction and repositioning

-

Multiple fixes across sub-spindle cutting, links, Z-position translations, and more

Bottom line:

Swiss machining is sensitive, and 2025.4 makes ESPRIT EDGE more predictable and safer for Citizen, Star, Tornos, and Tsugami environments.

Better Tool Cancel Positioning for CITIZEN Machines

You can now assign a tool-change or park position along Z independent of tool length.

This update gives you:

-

Safer, more controlled tool changes

-

Cleaner retract motion

-

Less manual editing

-

A default configuration you can store in the digital twin

For Swiss workflows, this simplifies a lot of tool handling.

Simulation Runs Faster

Simulation speed is improved by up to 15%, especially with:

-

4-axis milling

-

5-axis milling

-

Fine stock automation

Not a headline feature, but it saves time every single day.

A More Stable, Consistent Programming Experience

2025.4 includes hundreds of fixes across the platform, touching:

-

Posts

-

Multi-channel and multi-spindle machines

-

Feature recognition

-

Knowledgebase

-

Stock automation

-

Turning and grooving

-

Simulation stability

-

Wire EDM

-

UI/UX behavior

These changes don’t make noise, but they make the software feel smoother and more dependable.

Final Thoughts

ESPRIT EDGE 2025.4 is a practical upgrade with improvements most shops will appreciate right away — cleaner toolpaths, safer Swiss programming, tighter canned cycles, and faster simulation.

If you’re planning to upgrade or want a walkthrough of any of these enhancements, our team at PMT is here to help.