WHY CHOOSE PMT?

EXPERT TRAINING:

Learn from our ESPRIT-certified trainers. On-site or virtually. Become an expert.

DEDICATED SUPPORT:

Get ongoing assistance for all your manufacturing challenges. We're here to help you.

CUSTOMIZED IMPLEMENTATION:

Ensure a smooth transition to ESPRIT with our tailored implementation strategies.

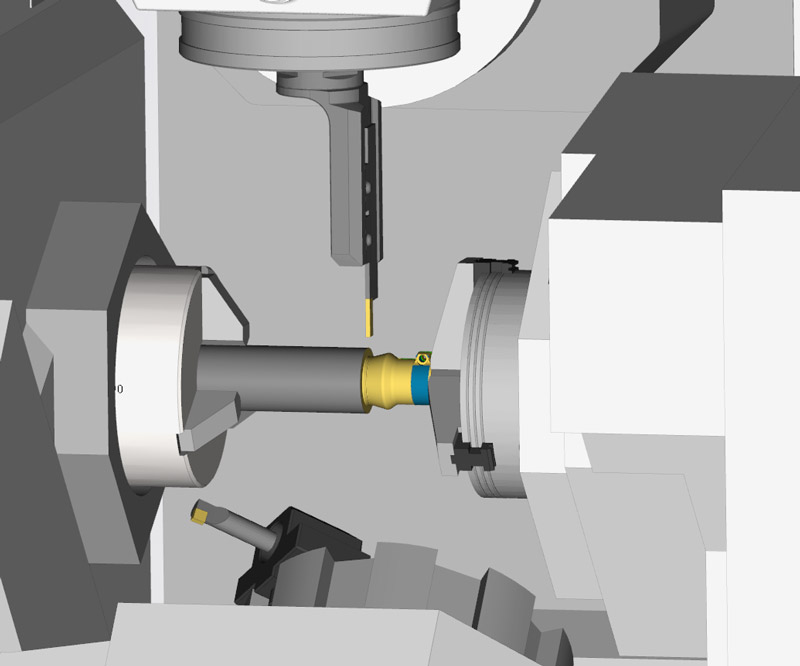

Transform Lathe Work with SolidTurn®

Unleash unparalleled flexibility on your CNC lathe, mill, or millturn machine with SolidTurn®. ESPRIT’s Modeless Programming allows you to integrate turning cycles with machining and inspection processes seamlessly, delivering machine-optimized, edit-free G-code. Quickly create rough and finish toolpaths tailored to various workpieces and scenarios. Customize each cycle for specific part needs and materials, ensuring optimized, collision-free paths with its stock-aware capabilities.

- Versatile turning cycles for any CNC machine configuration.

- Unified programming integrates turning with milling and probing for streamlined operations.

- Efficient toolpath generation for diverse workpieces and machining scenarios.

- Customizable toolpath control for unique part and material requirements.

Simplicity & Control

Roughing

SolidTurn's roughing cycles blend speed with control, offering multiple patterns and depth-of-cut strategies to fine-tune cycle times based on the material, geometry, and specific machining goals. Whether you're aiming for consistent cutting forces or minimizing deflection on delicate parts, SolidTurn provides the flexibility needed for optimal performance.

Key Features:

- Flexible tool orientations for comprehensive roughing applications.

- Customizable cycle times with various patterns and strategies.

- Adaptive to all machining needs, from standard to demanding applications.

- Efficient stock management for safe, collision-free machining.

Contour Turning

The contour turning cycle in ESPRIT delivers versatility for a range of roughing and finishing tasks, from profile cutting to complex 3D geometry machining. This cycle simplifies the machining of intricate profiles in a single pass, adapting to various cutting directions and strategies for ultimate flexibility.

Key Features:

- Versatile for both roughing and finishing tasks.

- One-pass machining of complex profiles.

- Flexible cutting strategies for different workpiece areas.

Grooving & Threading

Holemaking

ESPRIT’s suite of advanced holemaking cycles is expertly designed to accommodate a wide array of hole styles and machining strategies, whether leveraging a spinning tool, the workpiece itself, or both. These optimized toolpaths are the key to ensuring minimal cycle times for any number of holes, in any orientation, significantly boosting both efficiency and precision. Beyond these core capabilities, ESPRIT enhances the user experience by providing detailed control over the drilling process, allowing for adjustments that cater to specific machining requirements. This attention to detail ensures that each holemaking operation is not only swift but also tailored to the exact needs of the project, resulting in a seamless and highly efficient manufacturing workflow.

Key Features:

- Optimized toolpaths for rapid, precise holemaking.

- Flexible machining with spinning tool or workpiece options.

- Efficient for any hole style, in any orientation.

Part Handling & Stock Support

ProfitTurning®

ProfitTurning, a high-speed rough turning and grooving cycle, revolutionizes traditional turning with significantly higher speeds and efficiency. This innovative cycle manages cutter engagement to maintain consistent loads and forces, reducing vibration and stress for enhanced machining of delicate or hard materials.

Key Features:

- Significant cycle time reduction by 25%.

- Dramatic increase in tool life by 300%.