WHY CHOOSE PMT?

EXPERT TRAINING:

Learn from our ESPRIT-certified trainers. On-site or virtually. Become an expert.

DEDICATED SUPPORT:

Get ongoing assistance for all your manufacturing challenges. We're here to help you.

CUSTOMIZED IMPLEMENTATION:

Ensure a smooth transition to ESPRIT with our tailored implementation strategies.

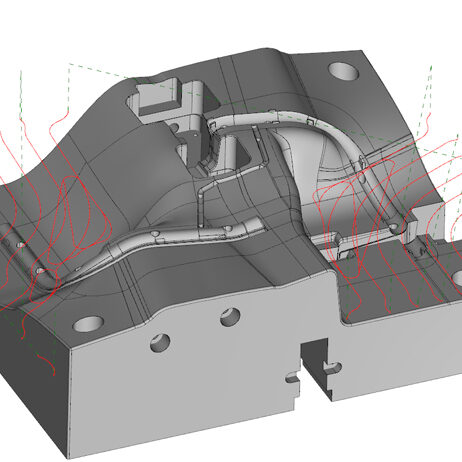

Advanced 3-Axis Machining Cycles

Elevate your machining capabilities with ESPRIT's advanced 3-axis machining cycles, designed for crafting complex freeform parts with precision and efficiency. Whether you're working in mold and die, tool making, discrete parts, or model-making, these cycles bring your 3D models to life, including those with surfaces, solids, and STL geometry. ESPRIT’s Modeless Programming™ allows these cycles to be seamlessly integrated on any mill, lathe, mill-turn, or Swiss-type machine, offering unparalleled flexibility. Combine these cycles within ESPRIT to create comprehensive part programs, optimizing your production process from start to finish.

Prefinishing

Finishing

Select from a comprehensive range of finishing strategies with ESPRIT, ensuring every surface is treated with the most appropriate technique for a superior finish. With nine finishing cycles to choose from, you can tailor your approach to each part, ensuring excellence in every detail.

Key Features:

- Wide range of finishing strategies.

- Tailored finishing cycles for superior results.

Remachining

Refine your parts to perfection with ESPRIT’s remachining cycles, targeting areas missed by larger cutters for a flawless finish. This smart strategy minimizes bench work and ensures complete surface coverage, even in the most challenging tight spots, without risking tool damage.

Key Features:

- Targeted remachining for flawless finishes.

- Minimizes manual bench work.

- Safe removal in tight spots without tool damage.

Stock-Aware Toolpath

High-Speed Machining

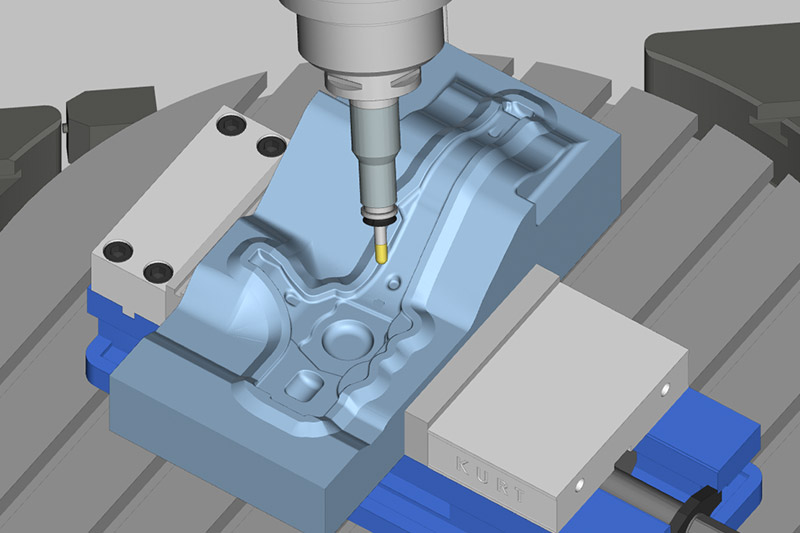

Simulation & Verification

Visualize and verify your machining process with ESPRIT before cutting begins, ensuring accuracy and efficiency. The dynamic simulation environment shows every machine action in real-time, with built-in part inspection to compare the designed and machined parts, guaranteeing precision in every project.

Key Features:

- Real-time machining process simulation.

- Built-in part inspection for accuracy.

- Detailed analysis and optimization tools.