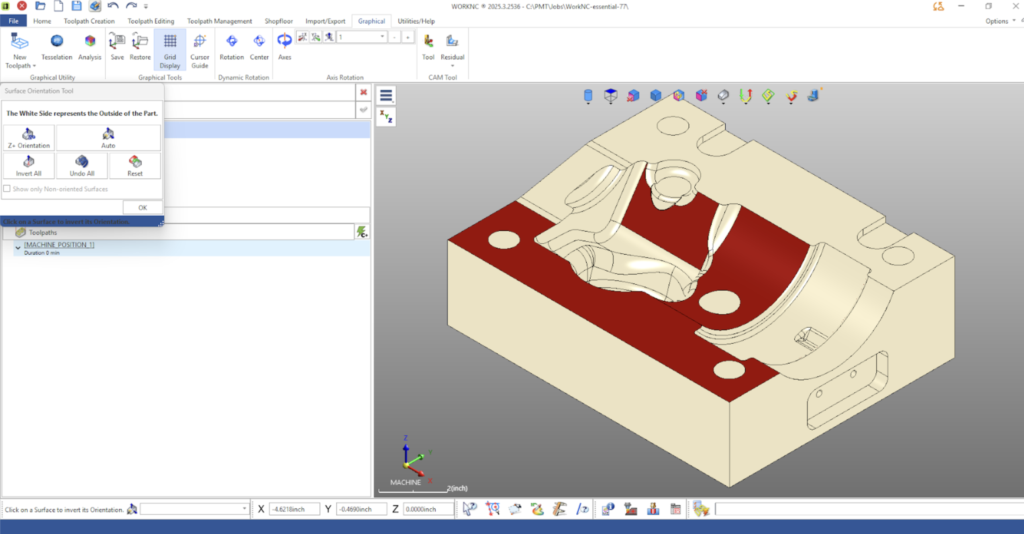

WORKNC – Analysis – Draft Angle

Using Draft Analysis in WORKNC for Smarter Toolpath Planning Understanding surface draft is a critical step in evaluating part manufacturability and selecting the correct machining strategy. WorkNC’s Draft Analysis tool provides a powerful and visual way to analyze surface angles, identify undercuts, and validate machining accessibility before toolpaths are created. In this article, we’ll walk…

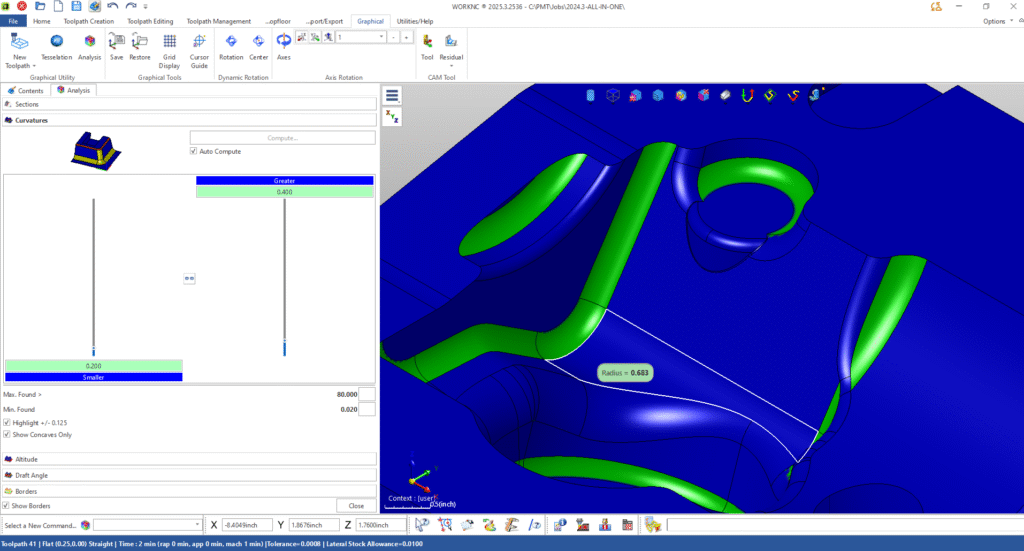

WORKNC Analysis: Understanding the Curvature Tool for Smarter Machining

In the world of precision machining, understanding a part’s geometry is critical for optimizing tool selection and toolpath strategies. WorkNC’s Curvature Analysis feature, found within the Analysis tab, gives machinists and programmers an efficient way to visualize and interpret surface radii across complex parts. This feature provides immediate feedback on geometry curvature, helping ensure that…

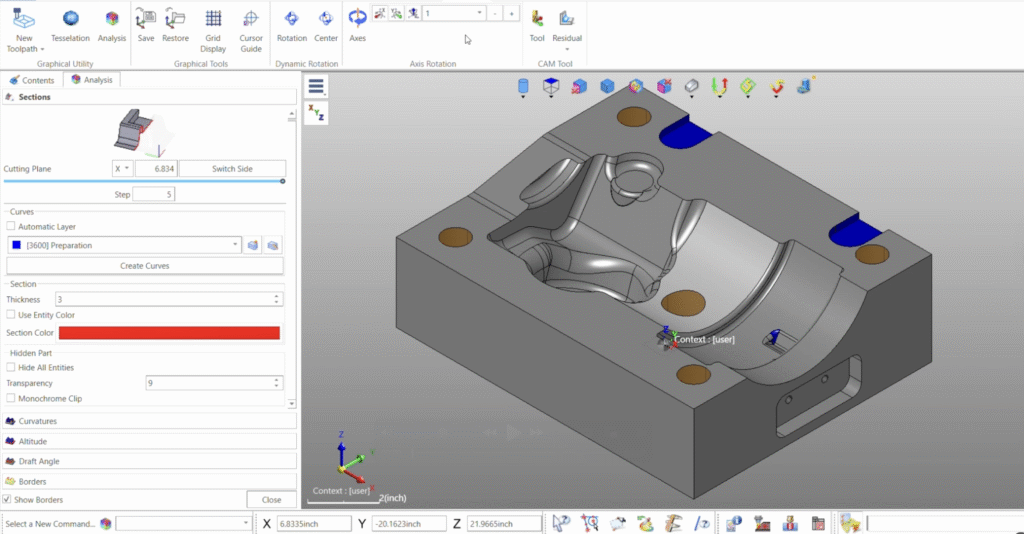

Using the Sections Tool in WORKNC Analysis

WORKNC is known for its powerful machining strategies, but one of its most underrated strengths lies in its Analysis tools. These tools allow programmers and machinists to better understand part geometry, identify potential issues, and prepare data for toolpath generation. Among them, the Sections command stands out as a versatile feature for visualizing and analyzing…

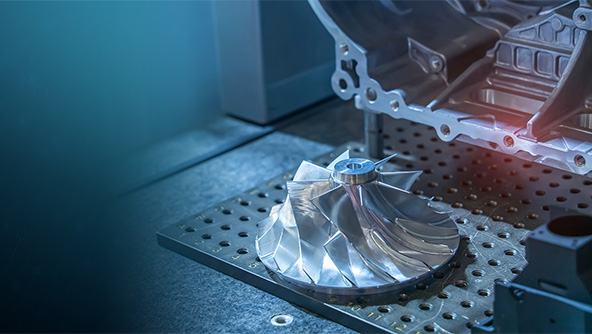

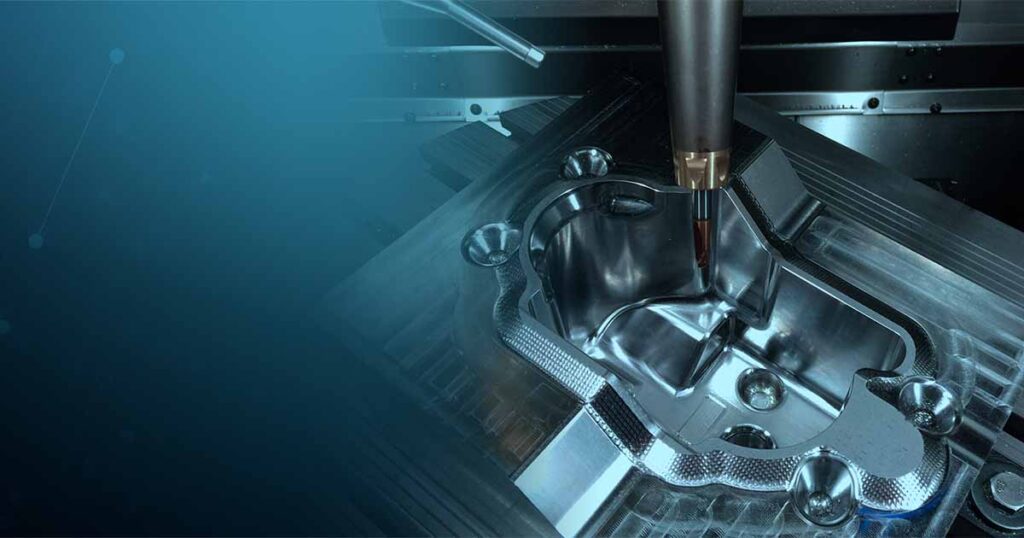

WORKNC 2025.1 is Here – Smarter, Faster, and More Flexible

The newest release of WORKNC 2025.1 brings big upgrades to the table, making your CAM programming smoother, faster, and more reliable. Whether you’re roughing, finishing, or verifying toolpaths, this version is built to boost your productivity. What’s New in WORKNC 2025.1? Next-Gen Toolpath InterfaceProgramming just got a lot easier. The redesigned interface lets you manage…

Introducing the WORKNC 2024.3 Release!

Hold on to your tool holders because WORKNC 2024.3 is here, and it’s about to change the way you machine! If you’re looking to boost productivity, cut machining time, and achieve a flawless finish, this is the update you’ve been waiting for. Here’s why everyone’s talking about it: More Info ACCESS the NEXUS link: https://nexus.hexagon.com/documentationcenter/en-US/bundle/worknc-2024.3-whatsnew/page/Content/Common/10000000034.htm…