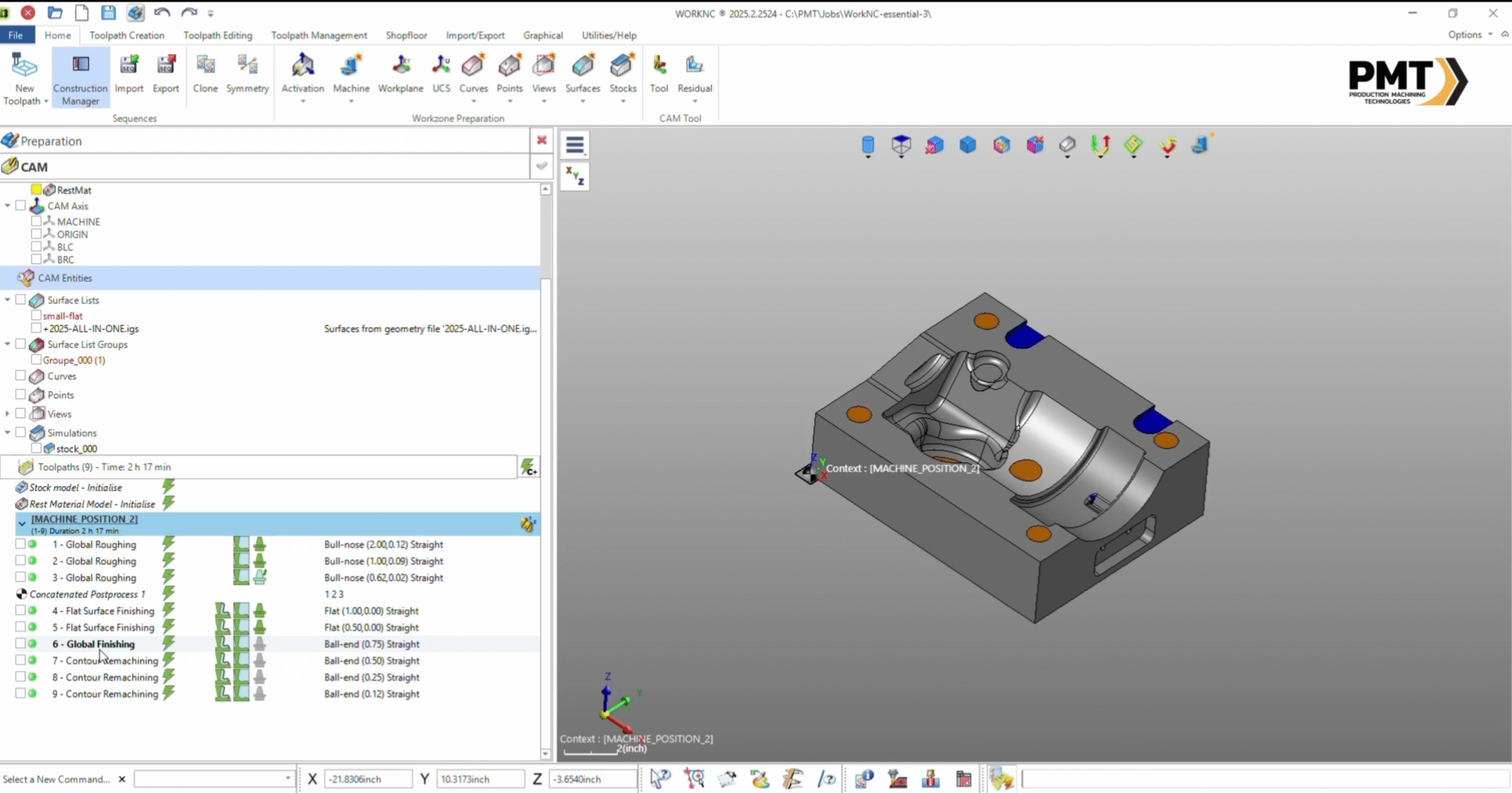

WORKNC Essential Training

This step-by-step course introduces you to the essentials of WorkNC—from software setup to workzone creation and model orientation. Build a solid foundation for toolpath programming at your own pace with 12 months of unlimited access.

$395.00

Description

Chapter 1 – Getting Started

- Open WorkNC

- Create a Workzone

- Set Translators, Tolerance, and Comments

- Adjust Surface Orientation

- Navigate the Interface: Shade, Rotate, Zoom, Pan ● Use the Mouse Tracker

- Position the Part

- Create and Align UCS

- Apply Machine Axis

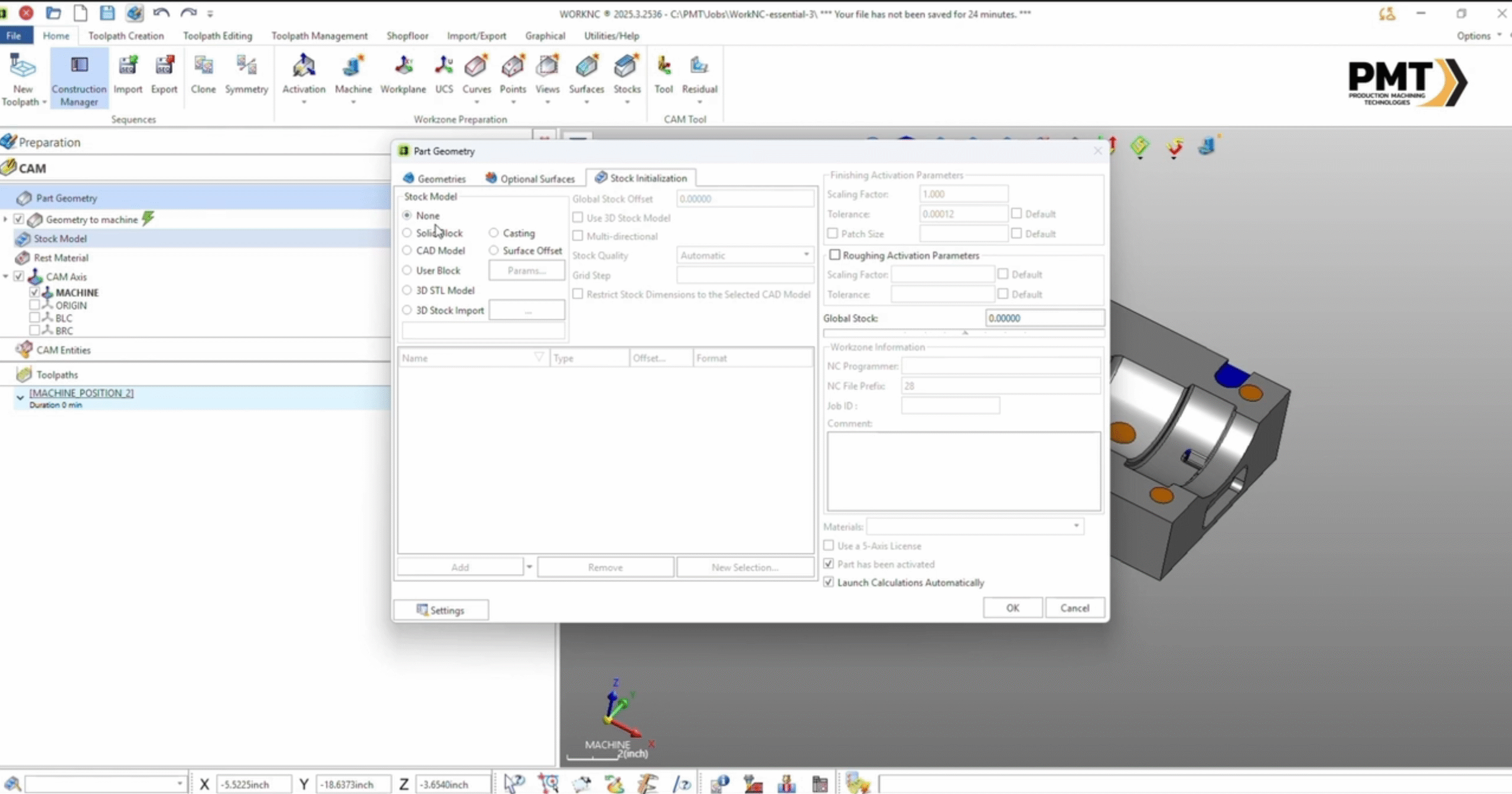

Chapter 2 – Stock Setup

- Create a Stock Model

- Use Different Geometrical Shapes

- Import Stock from CAD or Previous Jobs

Chapter 3 – Introduction to Toolpaths Menu Text:

- Understand Toolpath Organization

- Overview of Toolpath Styles

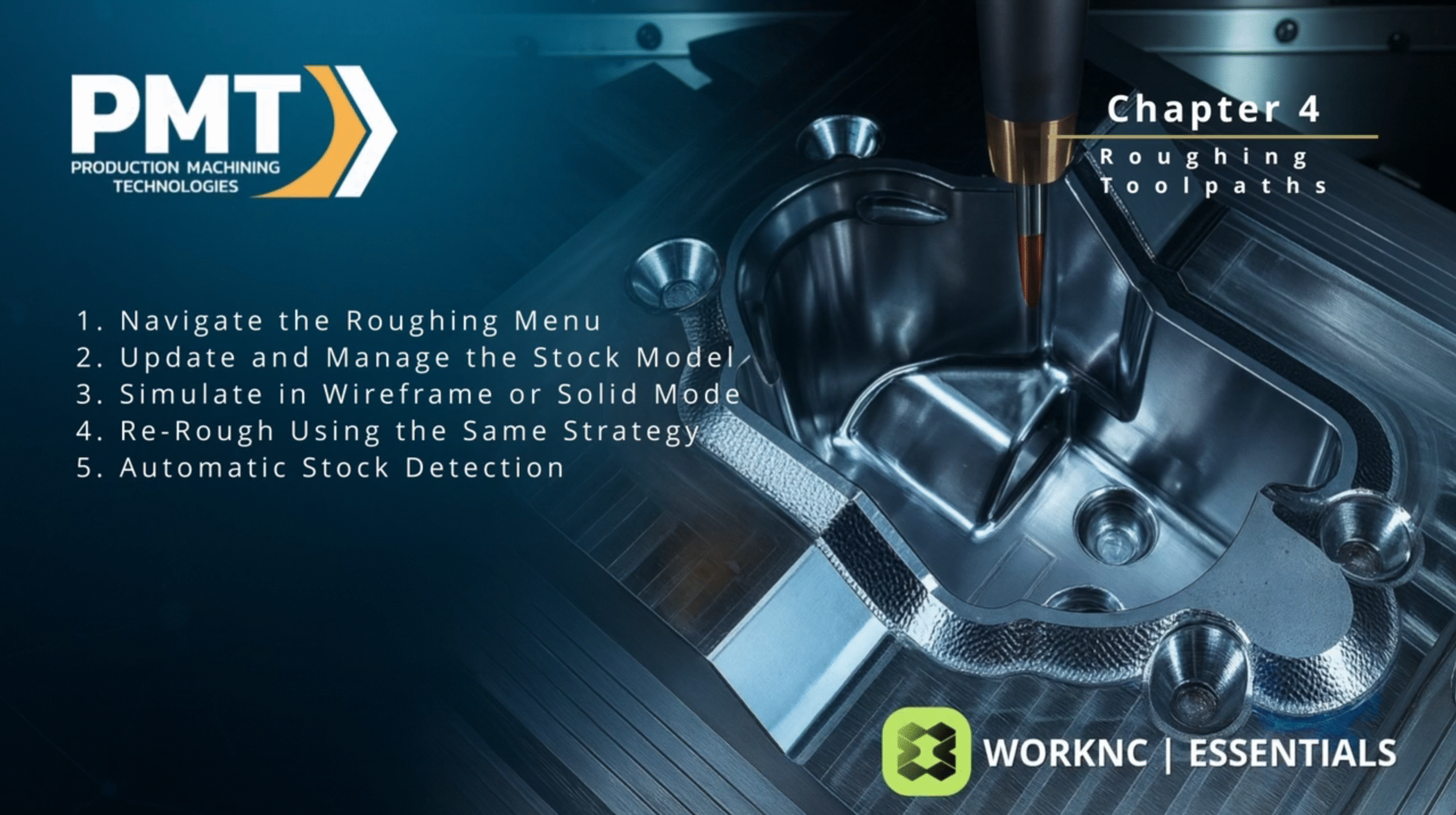

Chapter 4 – Roughing Toolpaths

- Navigate the Roughing Menu

- Update and Manage the Stock Model

- Simulate in Wireframe or Solid Mode

- Re-Rough Using the Same Strategy

- Automatic Stock Detection

Chapter 5 – Post Processing

- Select Post Processor

- Generate Code for Single or Merged Toolpaths

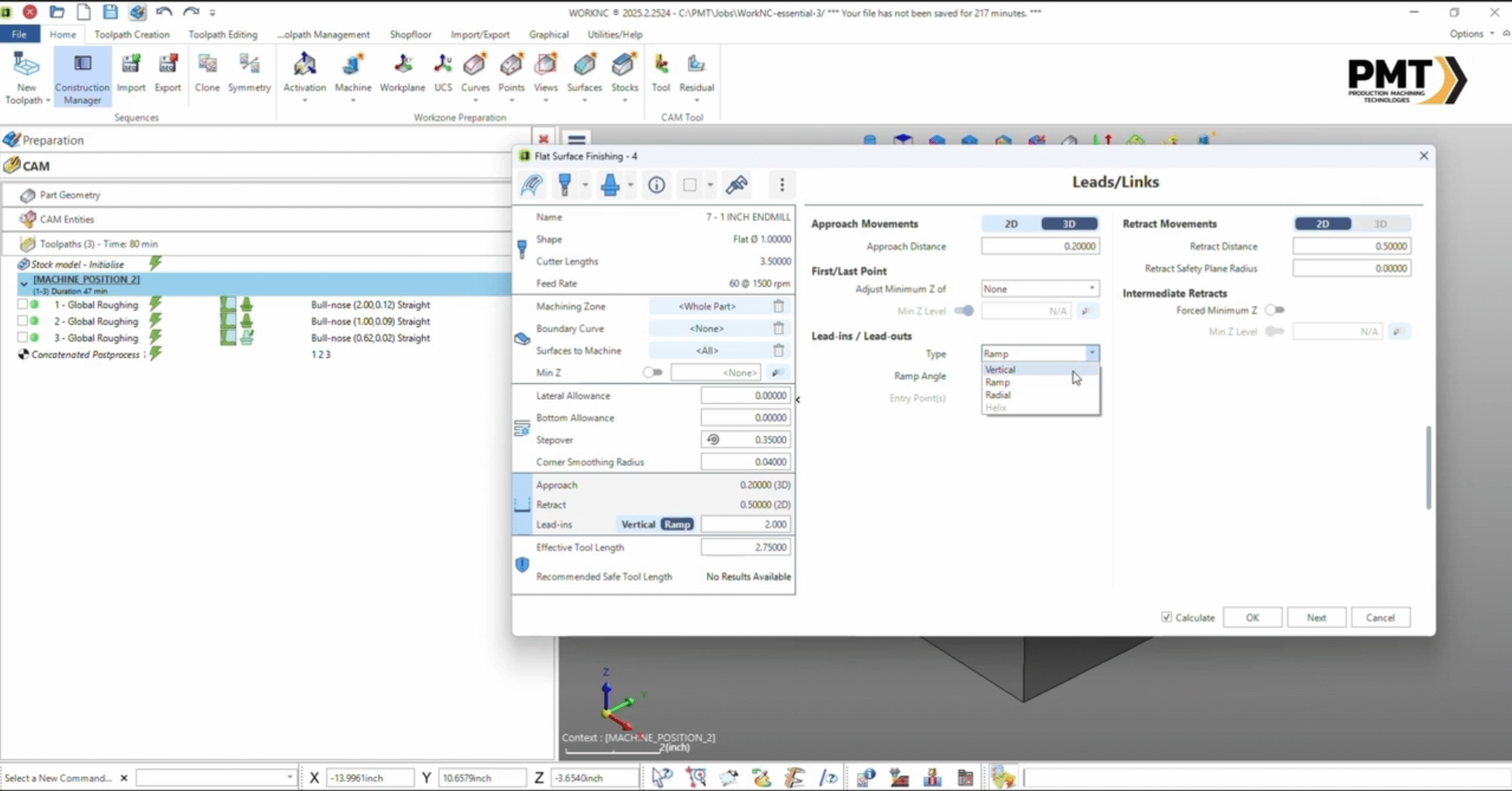

Chapter 6 – Finishing and Rest Machining Menu Text:

- Flat Surface Finishing

- Global Finish

- Rest Material Model

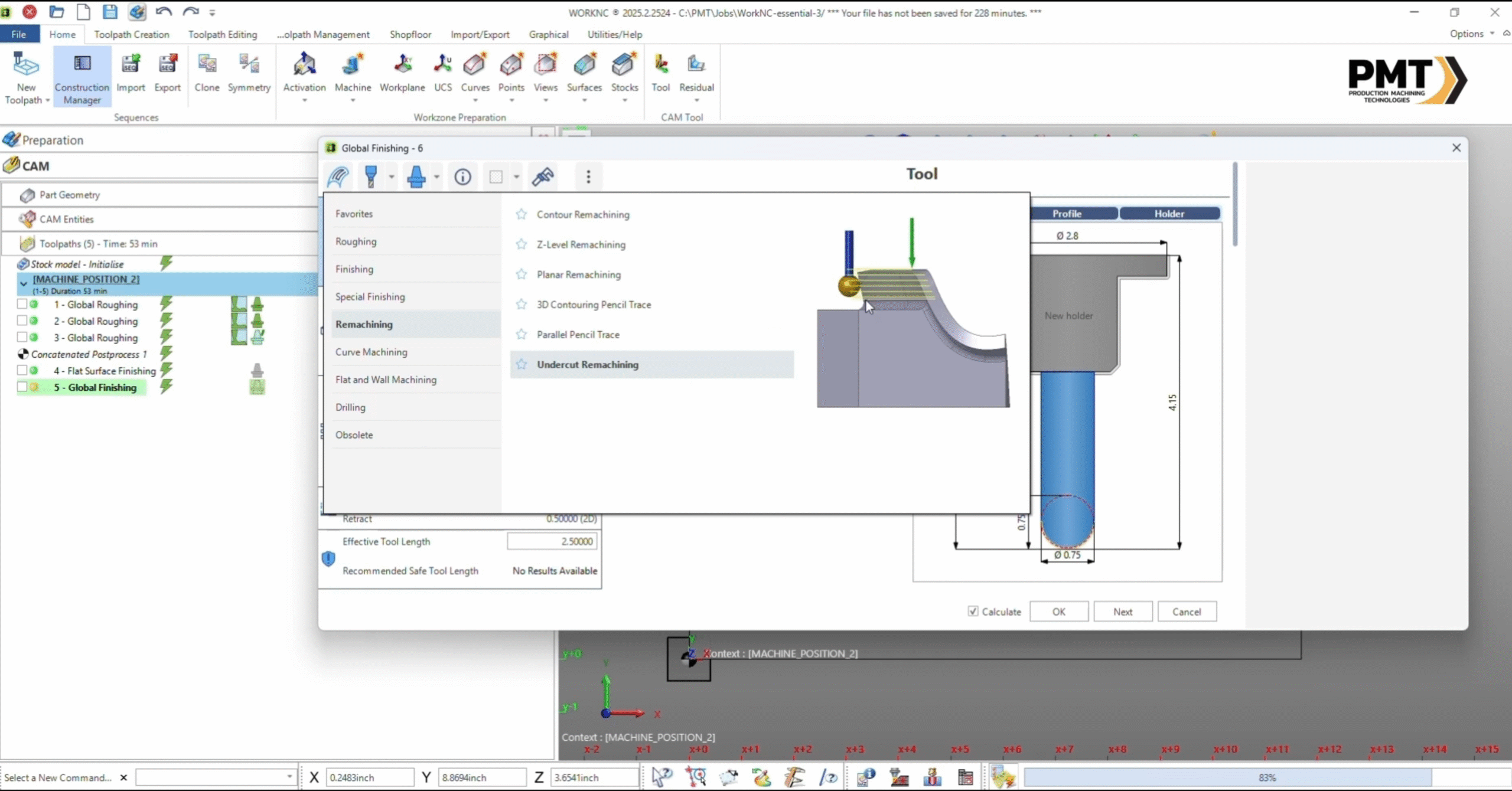

Chapter 7 – Re-machining

- Machining Corners and Tight Areas

- Remove Remaining Material

- View and Manage Leftover Stock

Chapter 8 – Tool Holders

- Calculate Minimum Tool Length

- Edit Toolpaths Automatically

- Optimize for Rigidity

Chapter 9 – Curves

- Create Boundary Curves

- Apply Limit Conditions

Chapter 10 – Surface Selection Menu Text:

- Select Surfaces to Limit Toolpaths ● Apply Alternate Stock Allowances ● Protect or Avoid Machining Areas

Chapter 11 – Toolpath Management Menu Text:

- Remove or Reorder Toolpaths ● Automatic Safety Move Adjustments