WHY CHOOSE PMT?

EXPERT TRAINING:

Learn from our ESPRIT-certified trainers. On-site or virtually. Become an expert.

DEDICATED SUPPORT:

Get ongoing assistance for all your manufacturing challenges. We're here to help you.

CUSTOMIZED IMPLEMENTATION:

Ensure a smooth transition to ESPRIT with our tailored implementation strategies.

Comprehensive Powder Bed Fusion Manufacturing Solution

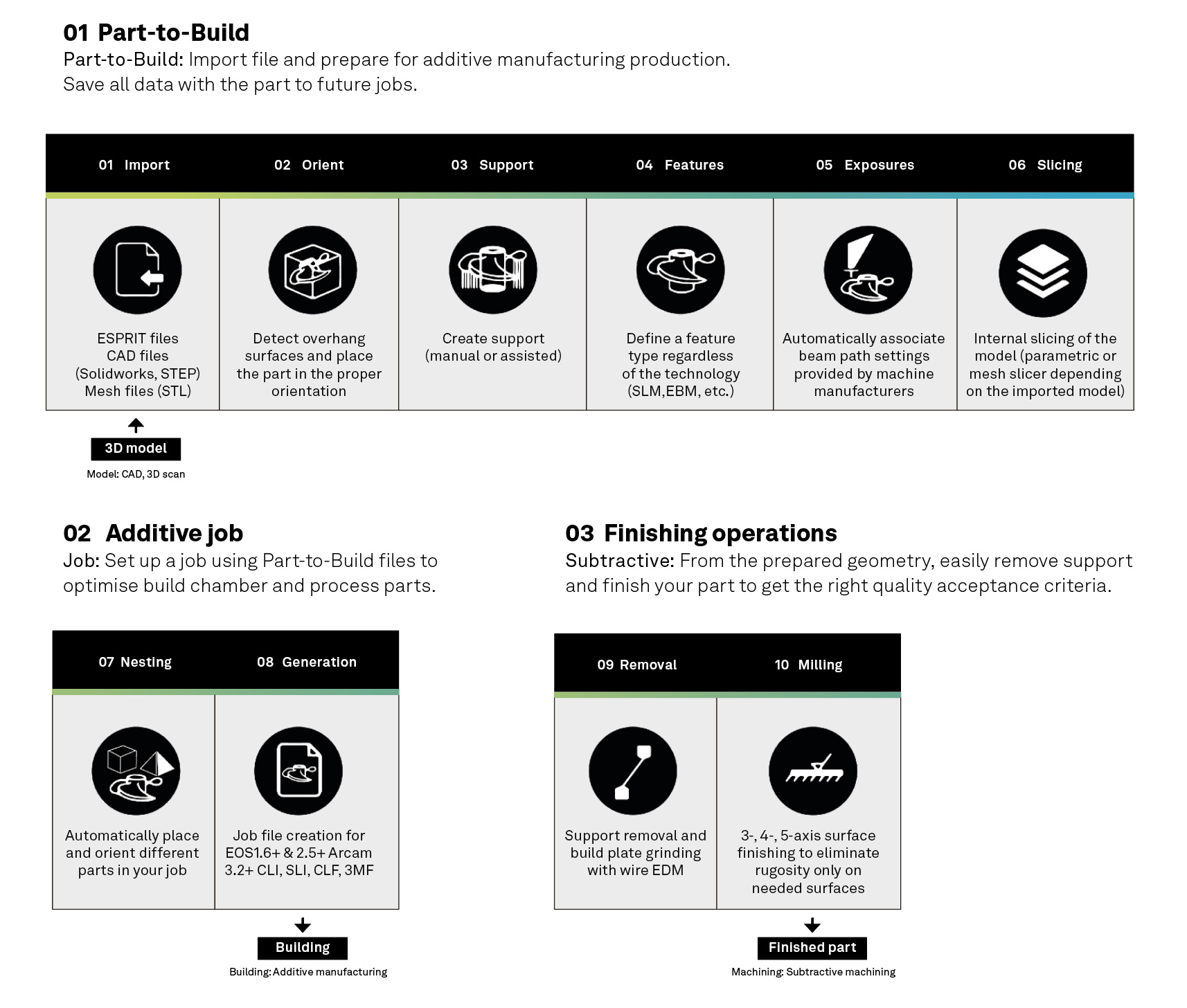

Optimized Part-to-Build Workflow

Discover unparalleled efficiency with our modular workflow designed to streamline your production from the ground up. By eliminating repetitive tasks, this approach significantly reduces preparation time, enhancing overall productivity. It guarantees traceability from the original 3D CAD file to the finished product, simplifying your manufacturing process. This system is engineered to improve your operational efficiency, ensuring a seamless transition from design to production, making it an essential tool for modern manufacturing environments.

- Time-saving with single preparation step

- Efficient, modular production process

- Guaranteed traceability back to 3D CAD file

- Streamlined manufacturing from start to finish

Single CAM Software

Leverage 35 years of innovation with our end-to-end PBF solution. This single software environment optimizes supports based on finishing needs and streamlines the process from CAD to machine file, all supported by unparalleled technical assistance. Simplify your additive manufacturing with a solution that embodies decades of ESPRIT innovation.

- Unified solution for additive manufacturing

- Intelligent support surface selection

- From CAD to machine file in one environment

- World-class technical support

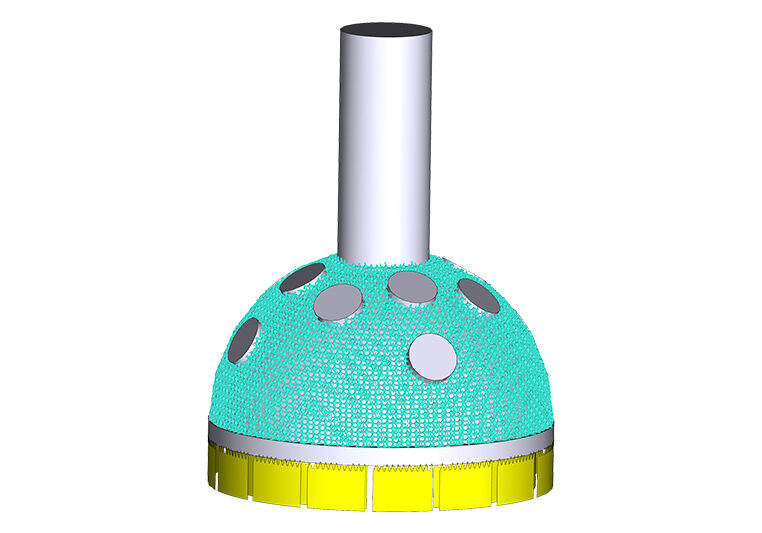

Assisted Part Preparation

Transform part preparation with our system's automated detection and intuitive support structure creation. By leveraging sophisticated algorithms, this feature streamlines the preparation phase, significantly enhancing build quality and efficiency. It intelligently assigns exposure strategies for different feature types, optimizing each build. This process not only simplifies workflow but also ensures that every part you produce meets the highest standards of precision and quality, making complex manufacturing tasks easier than ever.

- Automatic support surface detection

- Intuitive support structure generation

- Automatic exposure strategy assignment

- Optimized build quality and efficiency

Assisted Job Preparation

Maximize efficiency with our assisted job preparation features, which include advanced nesting capabilities and strategic build order optimization. This smart approach ensures efficient space utilization and collision-free designs, significantly enhancing productivity. By automating the arrangement and orientation of parts, our system streamlines the preparation process, reducing manual input and ensuring a more efficient build process. This feature is designed to optimize your additive manufacturing operations, delivering high-quality results with greater efficiency.

- Assisted nesting with collision detection

- Efficient patterned duplication for builds

- Strategic build order assignment

- Maximized build space utilization

Extensive Additive PBF Ecosystem

Engage with our broad ecosystem, featuring collaborations with top-tier machine manufacturers and cutting-edge research institutions. Our commitment to innovation and customer satisfaction drives us to continuously update and enhance our product offerings, ensuring you have access to the latest advancements in additive manufacturing. This expansive network supports a wide array of manufacturing needs, from medical to aerospace, providing solutions that are as diverse as they are advanced. Step into the future of manufacturing with a partner that understands and addresses your unique requirements.

- Collaborations with leading machine manufacturers

- Partnerships with top additive research institutions

- Continuous innovation tailored to customer workflows

- Access to factory-certified machine files