Posts by Matt Ryan

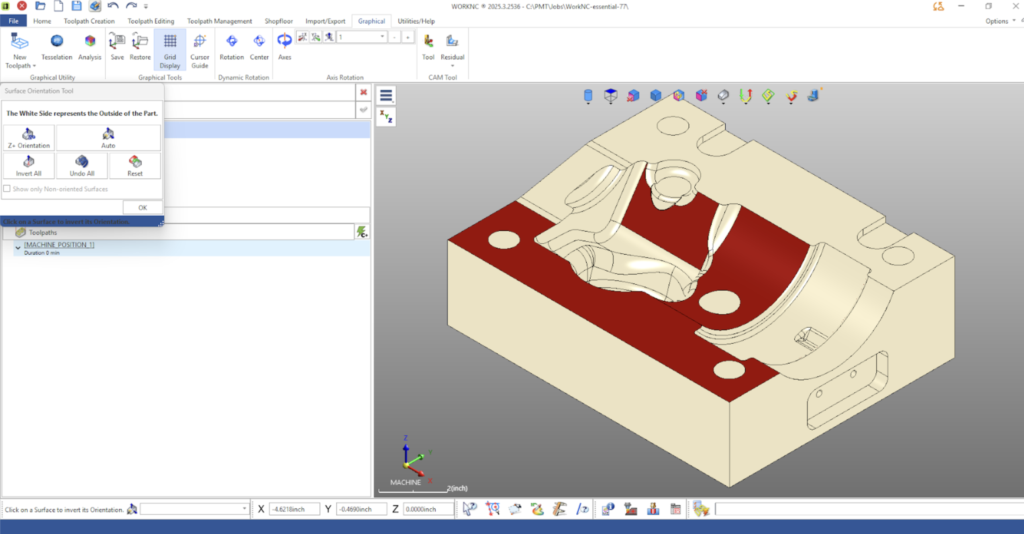

WORKNC – Analysis – Draft Angle

Using Draft Analysis in WORKNC for Smarter Toolpath Planning Understanding surface draft is a critical step in evaluating part manufacturability and selecting the correct machining strategy. WorkNC’s Draft Analysis tool provides a powerful and visual way to analyze surface angles, identify undercuts, and validate machining accessibility before toolpaths are created. In this article, we’ll walk…

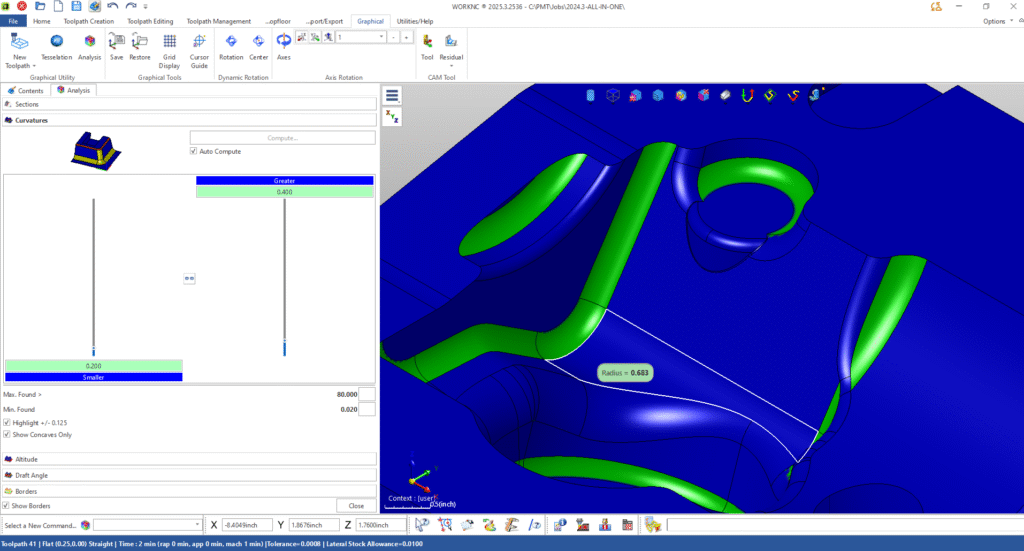

Read MoreWORKNC Analysis: Understanding the Curvature Tool for Smarter Machining

In the world of precision machining, understanding a part’s geometry is critical for optimizing tool selection and toolpath strategies. WorkNC’s Curvature Analysis feature, found within the Analysis tab, gives machinists and programmers an efficient way to visualize and interpret surface radii across complex parts. This feature provides immediate feedback on geometry curvature, helping ensure that…

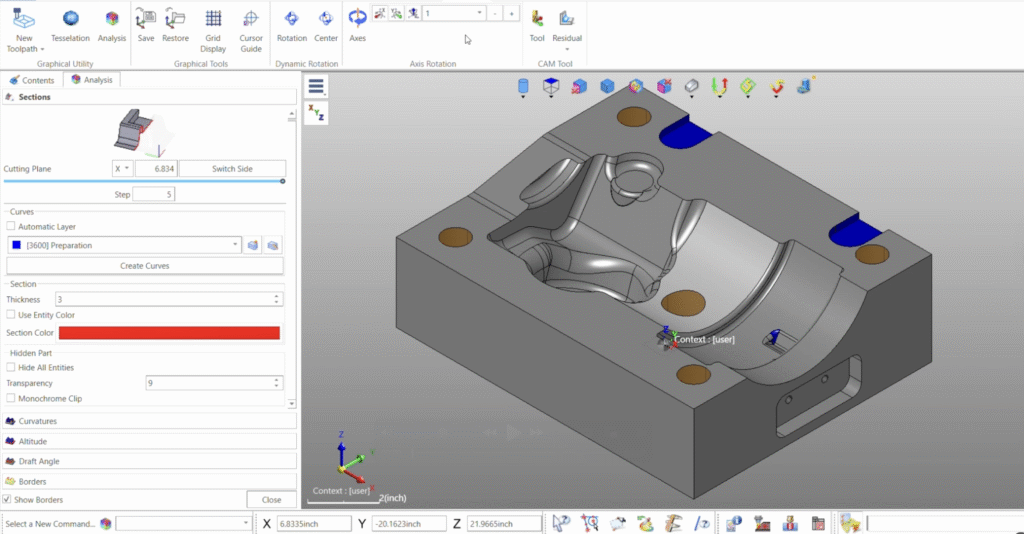

Read MoreUsing the Sections Tool in WORKNC Analysis

WORKNC is known for its powerful machining strategies, but one of its most underrated strengths lies in its Analysis tools. These tools allow programmers and machinists to better understand part geometry, identify potential issues, and prepare data for toolpath generation. Among them, the Sections command stands out as a versatile feature for visualizing and analyzing…

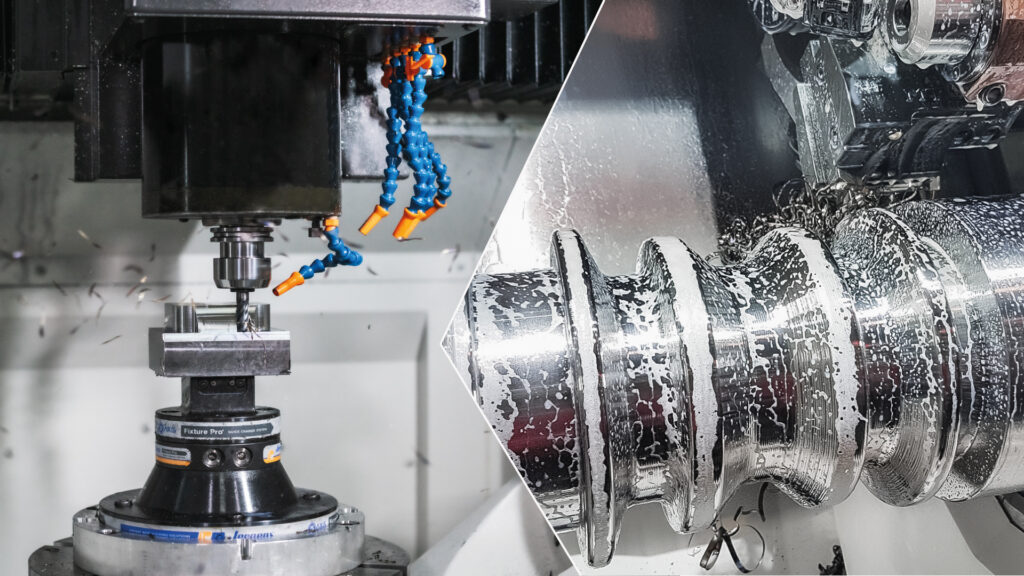

Read MoreUnderstanding Cutter Compensation and Offset Register Value in ESPRIT EDGE

Cutter compensation is one of the most critical—and occasionally misunderstood—features in CNC programming. In ESPRIT Edge, understanding how offset values influence both simulation and machine behavior is essential for accurate toolpath validation and production-ready G-code. This post focuses on a specific issue many users encounter: a simulation where the tool appears to drill directly into…

Read MoreHow to Add an Indexable Holder to a Turret in ESPRIT EDGE 2025

In modern CNC programming, accuracy begins long before the first chip falls. It starts with proper digital setup—especially for complex tool assemblies like indexable holders. ESPRIT Edge 2025 offers a streamlined way to simulate these assemblies, ensuring fidelity between your CAM environment and shop floor reality. This guide walks you through the process of adding…

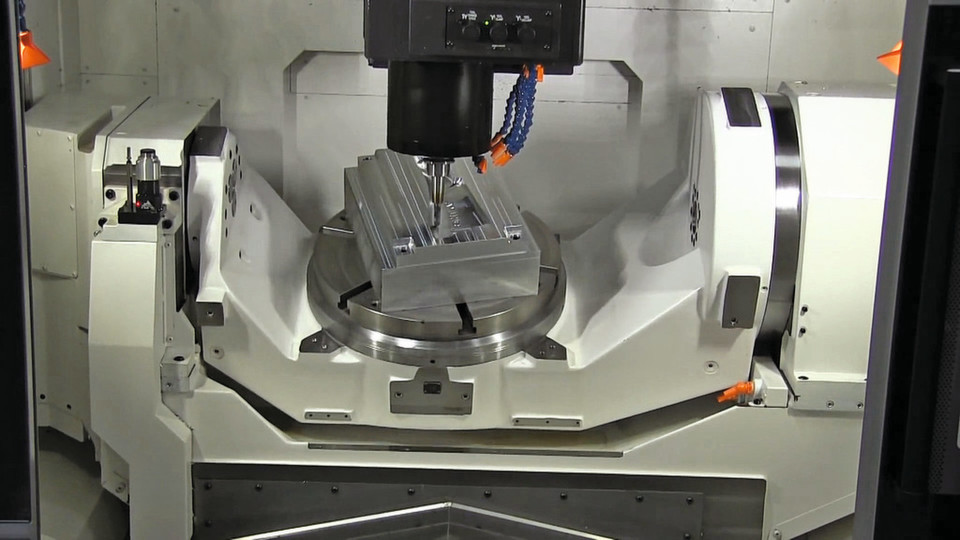

Read MoreSetting Up a Rotary Table in ESPRIT: A Step-by-Step Guide

Working with 5-axis parts in ESPRIT? If your machine setup includes a rotary table, replicating that configuration in your virtual environment is essential for accurate simulation and reliable toolpaths. Here’s a quick guide to help you set it up correctly in ESPRIT. Step 1: Launch ESPRIT with a New File Open ESPRIT and start fresh.How:…

Read More