Wire Electrical Discharge Machining (Wire EDM) stands as a cornerstone of precision manufacturing. It offers unmatched capabilities in the cutting of hard materials with intricate designs. Paired with Computer-Aided Machining (CAM) Software, wire EDM manufacturing offers some of the most accurate cutting capabilities in the world.

Understanding Wire EDM Technology

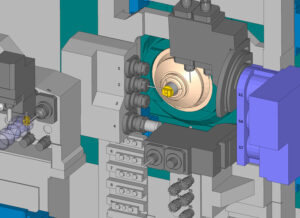

Wire Electrical Discharge Machining (Wire EDM) is a sophisticated manufacturing technique where a thin metallic wire serves as an electrode to cut or shape conductive materials through precisely controlled electrical discharges. This section explores the process in greater detail:

- Setup and Operation: The setup involves loading a wire, typically made from brass or zinc-coated materials for enhanced conductivity and strength, into the EDM machine. The wire is threaded through precision guides above and below the workpiece, and is continuously fed from a spool to ensure uninterrupted operation. This setup is crucial for maintaining the integrity of the cut and for facilitating complex, continuous patterns or shapes without manual intervention.

- Mechanism of Electrical Discharge: In Wire EDM, the removal of material from the workpiece occurs through a series of rapid electrical discharges between the wire and the workpiece. These discharges produce intense heat that melts or vaporizes the material in very localized areas. A key component in this process is the dielectric fluid, usually deionized water, which acts as an insulator until the electrical voltage between the wire and the workpiece reaches a threshold that breaks down the insulating strength of the fluid, initiating a spark. This fluid also cools the processed area and flushes away the eroded metal particles, which is essential for achieving a clean cut.

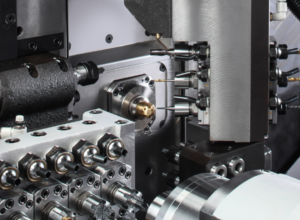

- Precision and Capabilities: Wire EDM is renowned for its precision. The technology can achieve tolerances as tight as a few micrometers, which is crucial for industries that require highly detailed work, such as aerospace and micro-manufacturing. The ability to maintain these tight tolerances makes Wire EDM ideal for producing intricate designs such as extrusion dies, complex gears, and other sophisticated assemblies. Moreover, the no-contact and force-free nature of the electrical discharge means that even very delicate parts can be machined without any physical distortion.

- Material Considerations and Limitations: While Wire EDM is versatile in its material capabilities, it is primarily used with metals and alloys that are electrically conductive. This includes hardened tool steel, titanium, aluminum, and certain types of superalloys. One of the limitations of Wire EDM is its speed; the process is generally slower than other forms of machining due to the careful control of the electrical discharges and the necessary frequent replacements of the wire electrode. Additionally, the need for the material to be conductive excludes non-metallic materials unless they are combined with conductive materials.

- Applications in Industry: The precision and versatility of Wire EDM make it indispensable in manufacturing sectors that demand meticulous detailing and exacting standards. For example, in the aerospace industry, it is used to form integral components that must fit with tight seals and withstand high pressures. In the tool and die industry, Wire EDM is used to create complex mold geometries that would be difficult or impossible to achieve through traditional machining.

The Role of CAM Software in Wire EDM

Advanced CAM (Computer-Aided Manufacturing) software is pivotal in modern Wire EDM processes, transforming digital designs into precise machining commands and enhancing operational efficiency. Here’s a deeper dive into how CAM software plays a crucial role:

- Advanced Path Planning: CAM software not only automates the path of the wire through the workpiece but also optimizes the path to reduce machining time and wire consumption. The software calculates the most efficient route for the wire, considering factors like cutting angles, entry, and exit points. This reduces the need for manual adjustments and allows for the production of parts with complex geometries or tapered surfaces without compromising on precision.

- Enhanced Simulation Capabilities: Modern CAM solutions incorporate sophisticated simulation tools that enable operators to visualize the entire machining process in a virtual environment before actual production begins. This feature helps in identifying potential errors like collisions between the wire and the workpiece, predicting instances of wire breakage, and assessing the effects of heat on different parts of the material. By foreseeing these issues, adjustments can be made preemptively, thereby reducing material waste and machine downtime.

- Comprehensive Parameter Optimization: CAM software facilitates the meticulous selection and control of various machining parameters, such as pulse duration, frequency of sparks, voltage settings, and flushing pressures. By fine-tuning these parameters, the software ensures optimal machining conditions tailored to specific materials and desired finishes. This level of control is crucial for maximizing surface integrity, reducing thermal damage, and achieving superior accuracies.

- Real-Time Monitoring and Feedback: Some advanced CAM systems are equipped with real-time monitoring capabilities that track the performance of the Wire EDM process and provide instant feedback. This allows for immediate corrections to the machining parameters if they deviate from the optimal conditions, ensuring consistent quality throughout the production run.

- Integration with CAD and ERP Systems: High-end CAM software often features seamless integration with CAD (Computer-Aided Design) software and ERP (Enterprise Resource Planning) systems. This integration facilitates a smoother workflow from design to production and inventory management. It allows for direct importation of 3D models from CAD software, which are then used to generate machine paths. Additionally, integration with ERP systems helps in scheduling jobs based on resource availability, tracking material usage, and managing maintenance schedules for Wire EDM machines.

- Adaptability and Customization: The best CAM systems offer high levels of adaptability and customization, allowing users to add specific modules or tools tailored to their unique manufacturing needs. This could include specialized algorithms for different types of wire or specific operations, custom filters for handling unique materials, or enhanced safety features that comply with industry regulations.

The adaptability and customization offered by advanced CAM software make it not just a tool, but a transformative asset for Wire EDM, empowering manufacturers to meet and exceed the evolving demands of precision engineering.

In the realm of precision manufacturing, the integration of Wire EDM with advanced CAM software such as Hexagon ESPRIT marks a significant leap forward. Hexagon ESPRIT's sophisticated capabilities streamline complex processes, reduce cycle times, and enhance product quality. By leveraging such powerful software, manufacturers can achieve unprecedented precision and efficiency, transforming challenges into opportunities for innovation and growth. With Hexagon ESPRIT, the future of manufacturing isn't just automated; it's optimized for excellence, making it the go-to solution for businesses aiming to stay at the cutting edge of technology.