Search Blog

- All

- DESIGNER

- ESPRIT

- ESPRIT EDGE

- NCSIMUL

- WORKNC

Setup Changes Made Easy

By Brent Addington

Transitioning between workholding setups within the same EDGE file. Traditionally, when setting up a new job that will ...

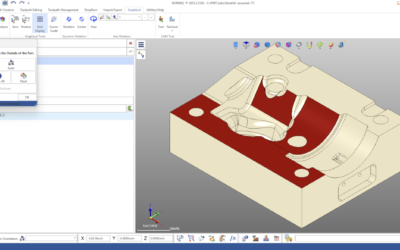

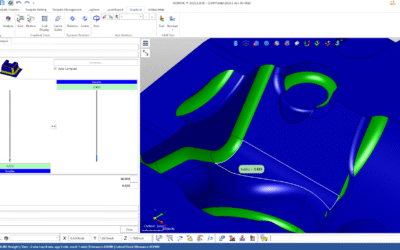

Read More WORKNC – Analysis – Draft Angle

By Matt Ryan

Using Draft Analysis in WORKNC for Smarter Toolpath Planning Understanding surface draft is a critical step in evaluating ...

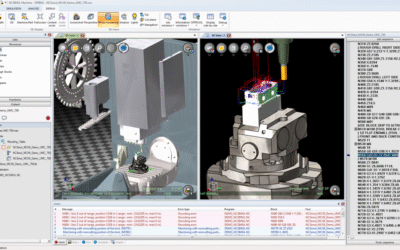

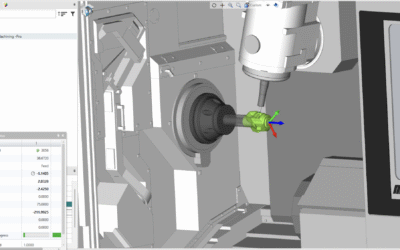

Read More ESPRIT EDGE 2025.4 — Practical Improvements You’ll Notice Right Away

By Mariano Torrez

ESPRIT EDGE 2025.4 is here, and this update is all about improving accuracy, toolpath quality, and day-to-day reliability. ...

Read More NCSIMUL 2025.4 – What’s New

By Mariano Torrez

We're excited to share the latest updates in NCSIMUL 2025.4, bringing improved simulation performance, new productivity tools, and ...

Read More The State of U.S. Manufacturing in 2025

By Mariano Torrez

The U.S. manufacturing industry continues to evolve - adapting to workforce shifts, automation, and new technologies faster than ...

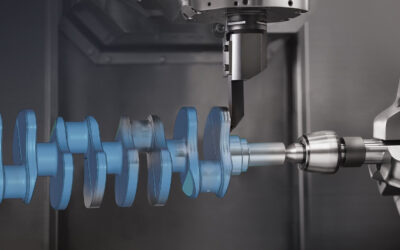

Read More Composite – Blending In

By Brent Addington

An Intro to 5-axis Composite Cycles. Blending Fillet with the 5th axis 1. Set your Workplane This time, ...

Read More WORKNC Analysis: Understanding the Curvature Tool for Smarter Machining

By Matt Ryan

In the world of precision machining, understanding a part's geometry is critical for optimizing tool selection and toolpath ...

Read More DESIGNER 2025.3

By Mariano Torrez

We're excited to announce that DESIGNER 2025.3 is here - bringing a smarter, faster, and more connected experience ...

Read More ESPRIT EDGE 2025.3 — Smarter, Faster, and Ready for What’s Next!

By Mariano Torrez

ESPRIT EDGE 2025.3 is officially out, bringing powerful enhancements that make programming smoother, faster, and more precise across ...

Read More Composite – Radial 5 Axis Machining

By Brent Addington

An intro to 5-axis composite cycles. Written in as few words as possible… 1. Set ...

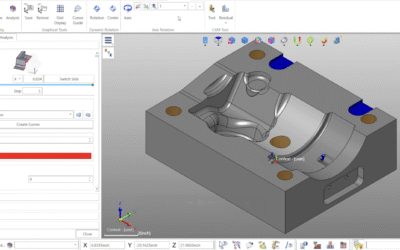

Read More Using the Sections Tool in WORKNC Analysis

By Matt Ryan

WORKNC is known for its powerful machining strategies, but one of its most underrated strengths lies in its ...

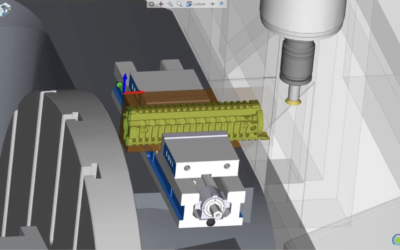

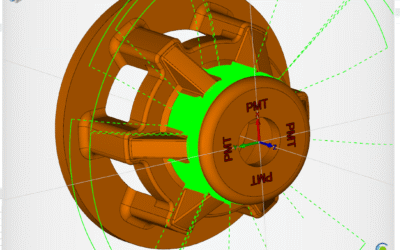

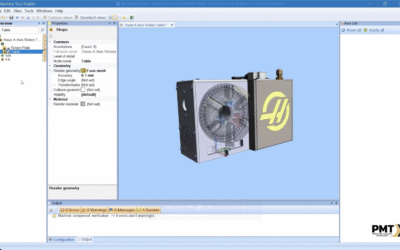

Read More Building a Rotary Table Fixture with ESPRIT EDGE & Machine Tool Builder

By Ben Wright

Integrating a rotary table fixture into your machining setup can significantly expand your capabilities-especially when working with complex ...

Read More