Precision manufacturing has dramatically evolved with the advent of technologies that enhance efficiency and precision. Among these, Swiss CNC machines are particularly noteworthy for their role in producing extremely precise components. Through decades of technological developments, Swiss turn machines have had massive impacts on various industries.

Technological Advancements in Swiss CNC Machines

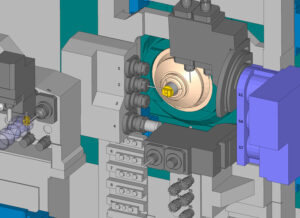

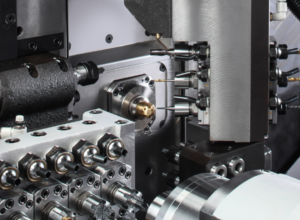

Originally simple manual devices, Swiss machines have transformed into highly complex systems controlled by computer numerical control (CNC). The hallmark of these machines, the sliding headstock mechanism, allows for continuous production without sacrificing accuracy. Modern Swiss CNC machines are capable of executing a variety of operations—turning, milling, drilling, and tapping—all within a single setup. This multifunctionality allows for the production of intricate components without the need to transfer the workpiece between different machines. The benefit of this all-in-one setup is significant reductions in cycle times and enhancements in overall precision.

Advances in digital control technology have expanded the capabilities of Swiss machines. Today's machines include sophisticated programming that can precisely control multiple axes simultaneously. This allows them to adapt to complex geometries and extremely fine details required by high-tech industries. The automation and precision enabled by these advanced systems reduce human error and significantly increase production consistency.

Innovations in Machine Design and Software Integration

Recent innovations have further improved the efficiency of Swiss CNC machining. These include cooling systems that allow for higher speed operations without compromising component quality. Additionally, the integration of real-time monitoring software provides operators with immediate feedback on machine performance and part quality. Continual innovations have led to more predictable and consistent outputs.

Additional software enhancements in Swiss turn machines now allow for better integration with CAD/CAM systems, like Hexagon Esprit. This enables operators to quickly and accurately translate design blueprints into machined parts. These advancements facilitate rapid prototyping and customization, which are increasingly demanded by industries such as automotive and consumer electronics.

Current State of Swiss CNC Machines in Industry

Swiss machines have become indispensable in any business that requires high levels of precision and efficiency. They are particularly crucial in the medical field, where precision is paramount for manufacturing critical components like bone screws and surgical instruments. These parts must adhere to strict specifications for safety and functionality, underscoring the importance of Swiss machining precision.

The aerospace and automotive industries also benefit from Swiss CNC technology in producing lightweight, high-strength components essential for safety and performance. The defense and electronics sectors also rely heavily on Swiss CNC machines for producing durable and reliable parts that meet rigorous quality standards.

Furthermore, the scalability offered by Swiss CNC machines makes them a critical asset in both prototyping and mass production phases. Manufacturers can swiftly transition from small to large production runs without sacrificing quality, a crucial capability for rapidly responding to market changes.

Impact on the Industry and Future Prospects

The adoption of Swiss lathe machines has transformed the manufacturing landscape. Their ability to efficiently produce complex parts with tight tolerances has not only improved product quality but also enhanced the profitability of precision manufacturing. The high level of automation and precision reduces waste and downtime, contributing to more sustainable manufacturing practices.

Looking ahead, the role of Swiss CNC technology is set to grow as industries continue to demand more intricate and precise components. Innovations in machine learning and artificial intelligence are poised to further enhance the capabilities of Swiss lathe machines, potentially leading to fully autonomous manufacturing systems.

Swiss CNC machines have evolved into pivotal components of modern manufacturing, pushing the limits of precision and efficiency. As industries advance, the demand for Swiss CNC technology will continue to expand, ensuring that manufacturers can effectively meet new challenges and maintain competitiveness in the global market.

To learn more about how Swiss CNC machines can enhance your production capabilities, get in touch with PM Technologies. We specialize in implementing advanced Swiss CAM systems like Hexagon Esprit, which are designed to optimize your manufacturing processes. Contact us today to explore how we can help you achieve exceptional precision and efficiency in your operations.