WHY CHOOSE PMT?

EXPERT TRAINING:

Learn from our ESPRIT-certified trainers. On-site or virtually. Become an expert.

DEDICATED SUPPORT:

Get ongoing assistance for all your manufacturing challenges. We're here to help you.

CUSTOMIZED IMPLEMENTATION:

Ensure a smooth transition to ESPRIT with our tailored implementation strategies.

Maximize Your CNC Machinery with ESPRIT

Unlock your CNC machinery's full potential with ESPRIT, tailored for programming, simulation, and G-code optimization across all machine tools, including horizontal, vertical, and gantry machines. Perfect for high-value parts and demanding applications, ESPRIT fits a broad range of industrial needs, from small job shops to large-scale manufacturing. By combining milling, turning, and probing into one unified program, ESPRIT helps you fully leverage your machine's capabilities, boosting productivity in your shop.

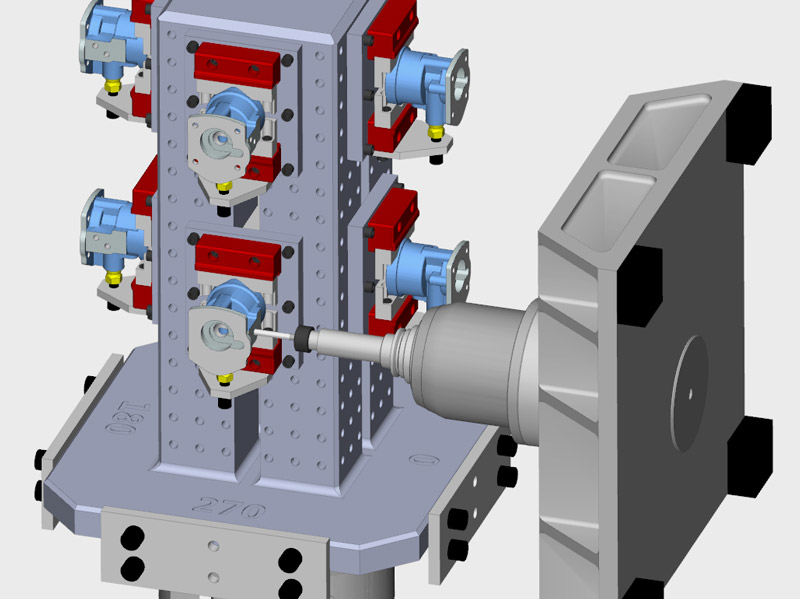

Program One Part, Machine Many

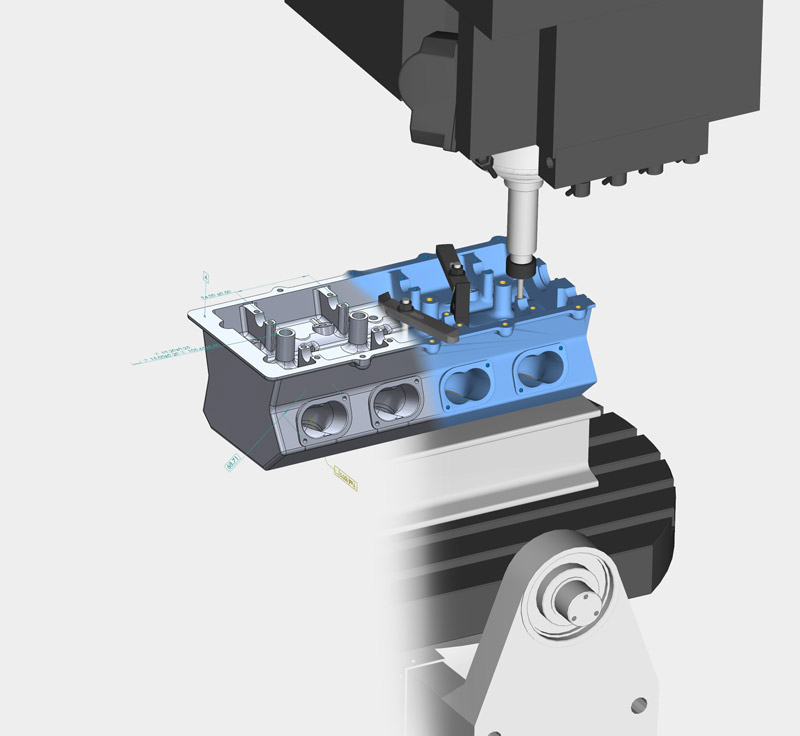

Programming with a Digital Twin

By utilizing a digital twin of your CNC machine, ESPRIT enhances programming accuracy and operational efficiency. This digital setup mirrors your shop's real environment, including tool assemblies and workholding, providing an in-depth "machine awareness" that informs better programming decisions. Automation of tasks such as link generation, cycle time optimization, and collision detection streamlines the programming process, ensuring optimal machine performance.

Key Features:

- Enhanced Machine Awareness: For informed programming decisions.

- Simplified Programming: With automated critical tasks.

- Optimized Machine Performance: On the shop floor.

Optimized Production

ESPRIT's intelligent optimization algorithms ensure maximum efficiency and machine utilization by minimizing tool changes, axis rotations, and travel distances. It considers operation dependencies and setup changes, streamlining the production process. Automatic tool and operation consolidation across multiple workpieces further enhances program efficiency.

Key Features:

- Cycle Time Optimization: For efficient part programs.

- Intelligent Setup Changes: Including part flips and transfers.

- Tool and Operation Consolidation: Across multiple workpieces.

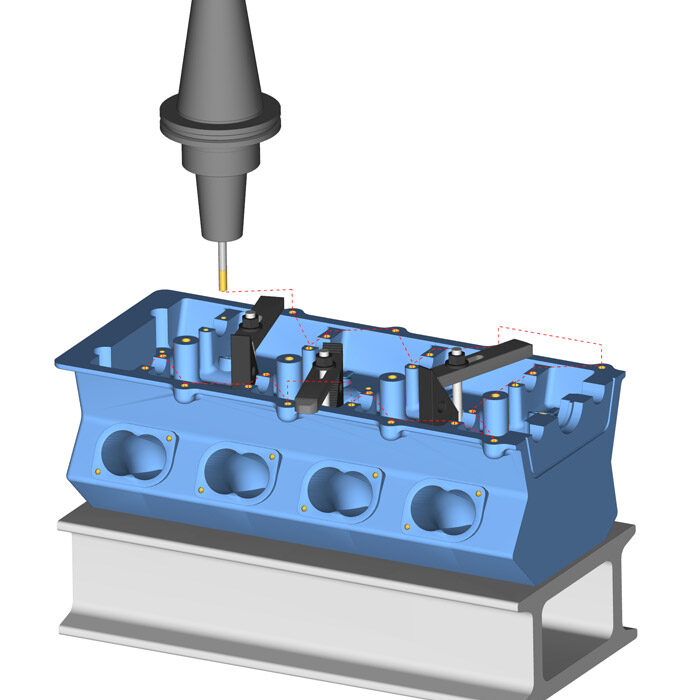

Intelligent Work Offsets

Automatic Link Generator