WHY CHOOSE PMT?

EXPERT TRAINING:

Learn from our ESPRIT-certified trainers. On-site or virtually. Become an expert.

DEDICATED SUPPORT:

Get ongoing assistance for all your manufacturing challenges. We're here to help you.

CUSTOMIZED IMPLEMENTATION:

Ensure a smooth transition to ESPRIT with our tailored implementation strategies.

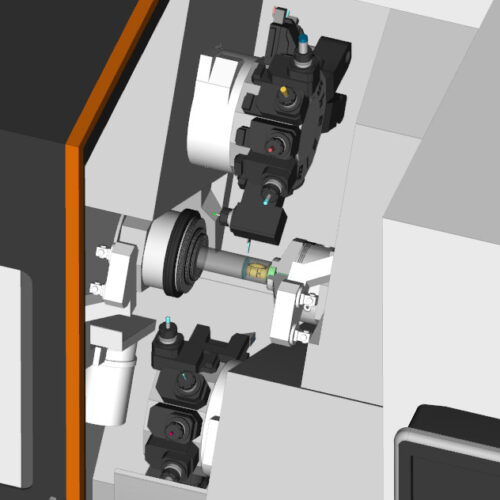

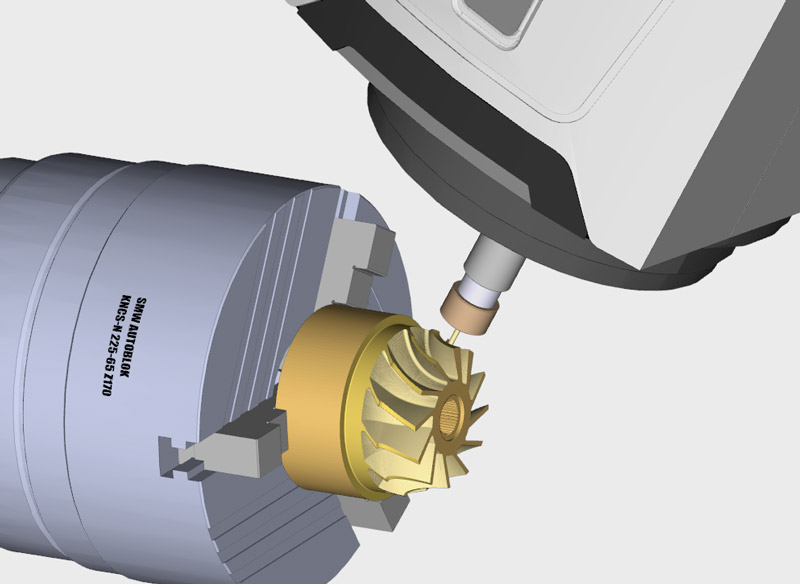

Unleash Mill-Turn Machine Potential

Unlock the full potential of your multifunction, multitasking, and multichannel mill-turn machines with ESPRIT. Tailored for a broad spectrum of industries—from aerospace and power generation to the precision required in electronics and medical device manufacturing—ESPRIT ensures you leverage every bit of your machine's capabilities. With an extensive array of machining cycles, coupled with superior process synchronization, program optimization, and precise machine simulation, you're equipped to produce edit-free G-code that perfectly matches your machine's abilities.

- Tailor-made for any machine and application, ensuring versatility across industries.

- Comprehensive machining cycles to tackle any manufacturing challenge.

- Advanced synchronization and optimization to streamline your processes.

- Accurate simulation and machine-optimized G-code for flawless execution.

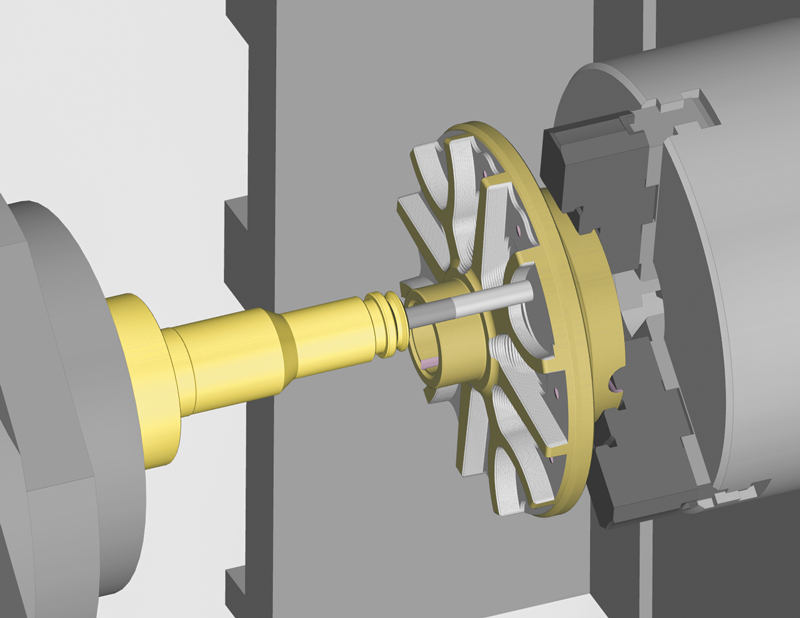

Milling on a Lathe, Turning on a Mill

Synchronized Machining

Minimize cycle times and maximize your machine's full capacity with ESPRIT's automatic synchronization of machining cycles. Whether you're optimizing short runs or aiming for maximum throughput with concurrent part cutting on main and sub-spindles, ESPRIT delivers a streamlined, optimized program that synchronizes machining cycles with intricate workpiece handling and setup changes.

Key Features:

- Automates synchronization for efficient machining and handling processes.

- Supports simultaneous machining of multiple parts, maximizing throughput.

- Minimizes cycle times, fully leveraging your machine's capacity.

- Ensures a comprehensive, optimized program, integrating machining cycles with part handling seamlessly.

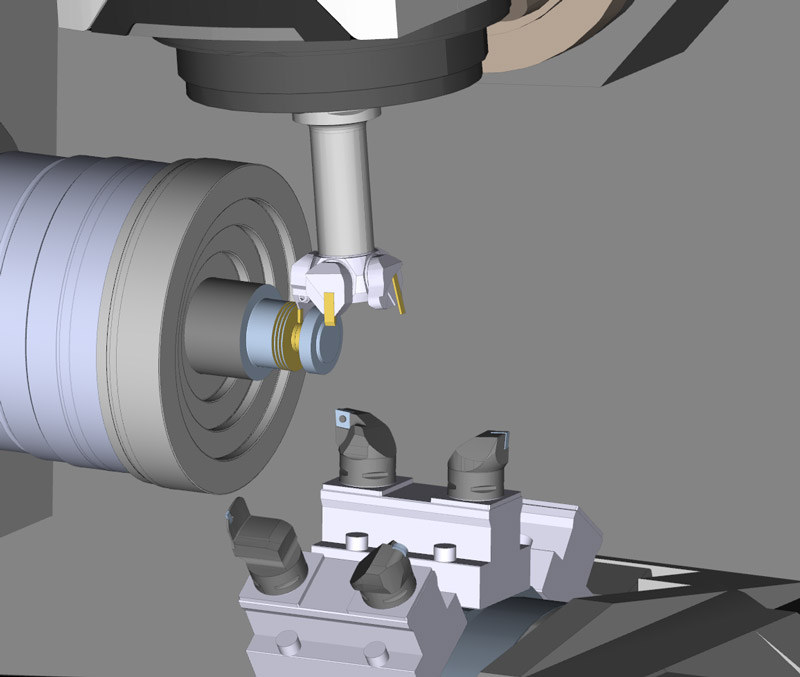

Automatic Link Generator

Navigate the complexity of multitasking machines with ESPRIT’s automatic link generator, which ensures collision-free, machine-optimized positioning and rapid moves. This indispensable tool not only safeguards your machine but also significantly reduces programming time and accelerates the on-machine prove-out process, ensuring all movements are executed safely and efficiently.

Key Features:

- Generates collision-free positioning and rapid movements automatically.

- Takes into account all machine components, enhancing safety and efficiency.

- Significantly reduces programming time, streamlining the prove-out process.

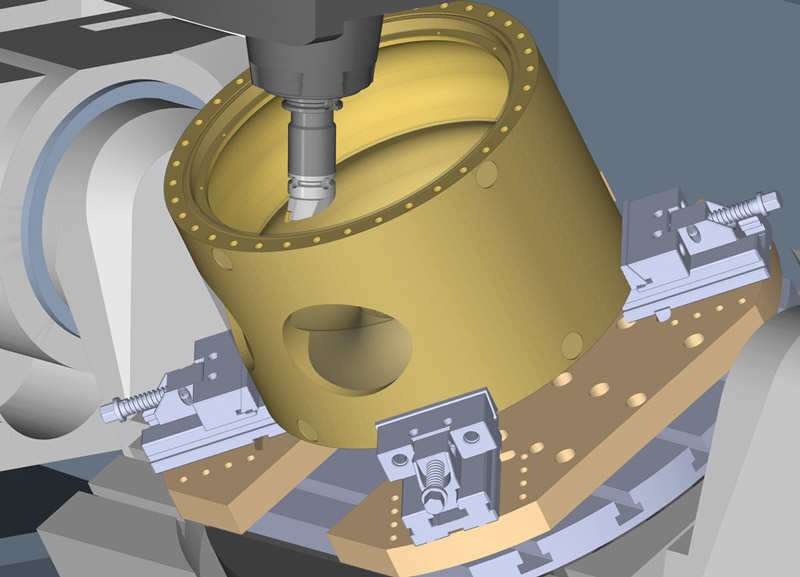

Adaptive Machining

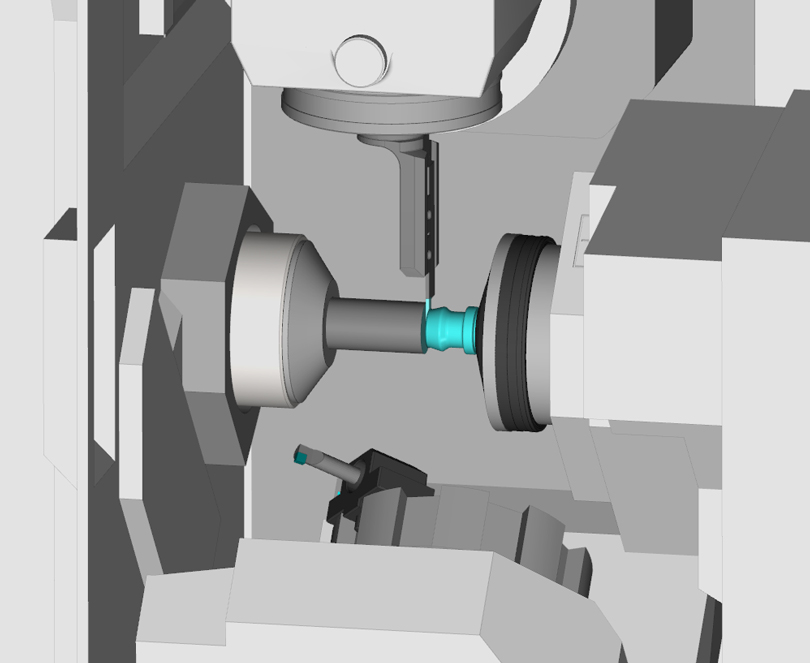

Full Machine Simulation & Verification

Experience the precision of ESPRIT’s full machine simulation, providing an animated, real-time view of your entire machining process. This simulation covers every machine component in action, offering detailed analysis and reports on potential violations, collisions, and channel conflicts. With the ability to start simulations at any program point, you can anticipate and resolve issues before they impact your manufacturing process.

Key Features:

- Real-time, accurate machining simulation for complete process visibility.

- Detailed analysis of cutting cycles and machine actions.

- Comprehensive reports on potential issues, ensuring preemptive problem-solving.

- Start simulations at any program point, enhancing troubleshooting and optimization.