WHY CHOOSE PMT?

EXPERT TRAINING:

Learn from our ESPRIT-certified trainers. On-site or virtually. Become an expert.

DEDICATED SUPPORT:

Get ongoing assistance for all your manufacturing challenges. We're here to help you.

CUSTOMIZED IMPLEMENTATION:

Ensure a smooth transition to ESPRIT with our tailored implementation strategies.

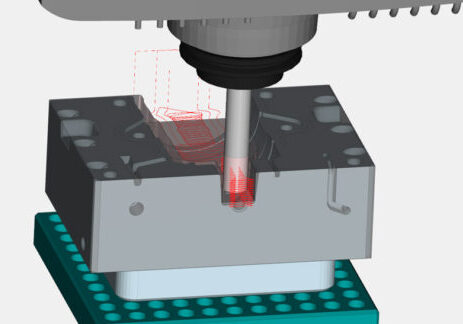

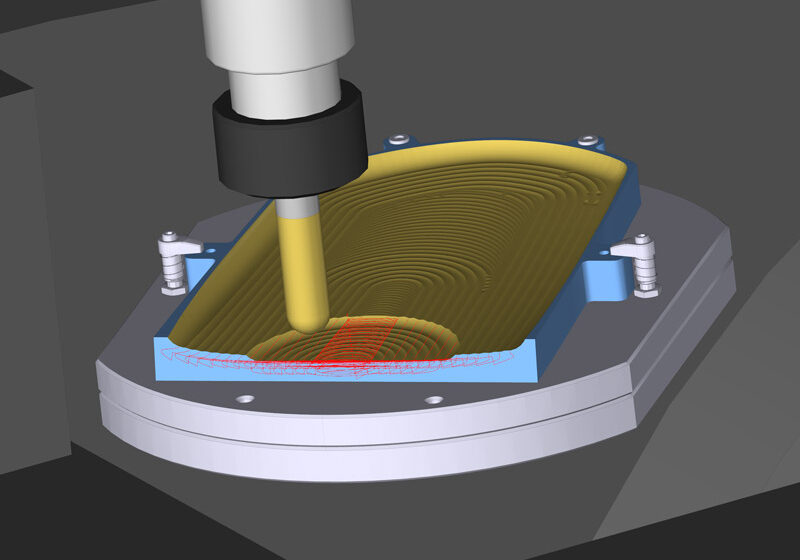

Maximize Efficiency with ESPRIT's ProfitMilling®

Discover the power of ESPRIT's ProfitMilling® for 2.5-, 3-, 4-, and 5-axis roughing, transforming your machining process with significantly reduced cycle times and a dramatic increase in tool life. This patented strategy combines optimized toolpaths, light radial engagements with full depths of cut, and dynamically optimized feed rates to ensure consistent chip loads and minimized cutting forces. This innovative approach not only boosts your productivity but also slashes operating costs, offering you:

- A staggering 75% reduction in cycle times

- An impressive 500% boost in tool life

- Optimize chip loads and cutting forces

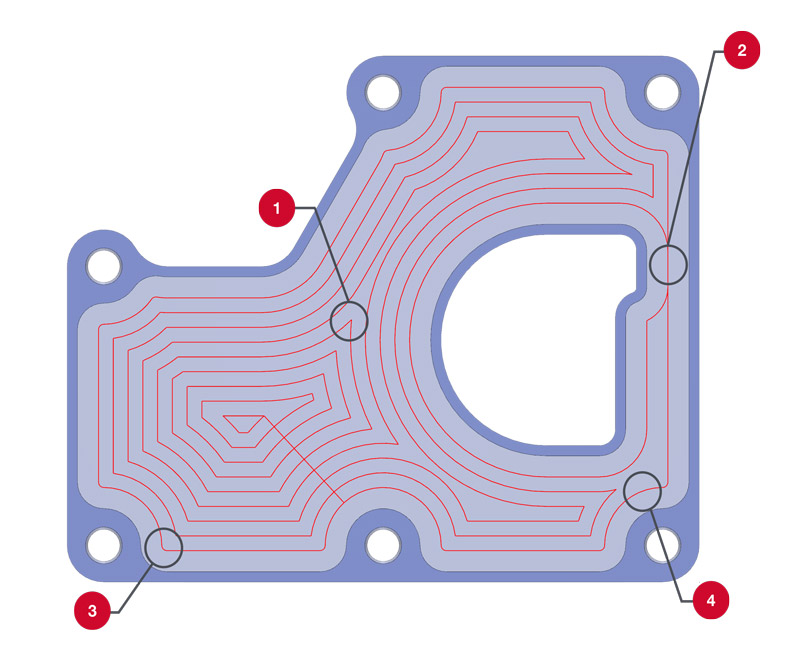

How ProfitMilling Works

Traditional Roughing Challenges

Traditional roughing methods often lead to longer cycle times due to the need for conservative cutting speeds, which compensate for chip load and acceleration inconsistencies. This approach can lead to:

- Increased cutting forces and machine "jerks" from sharp corners

- Cutter overload with full-width slotting

- Higher chip loads from variable tool engagement angles

- Inconsistent chip loads due to constant centerline feed rates

- Longer cycle times from cutting at multiple incremental depths

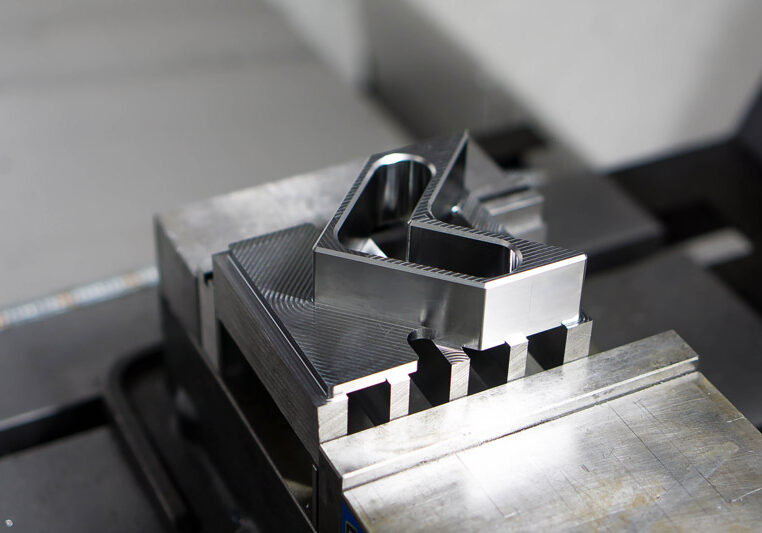

Roughing with ProfitMilling

ProfitMilling revolutionizes roughing, enabling deeper cuts and faster cutting speeds for shorter cycle times and extended tool life. This method introduces:

- Efficient chip evacuation with an initial spiral motion

- Smooth, consistent toolpaths and transitions

- Trochoidal slotting for constant chip load management

- Elimination of chatter and consistent tool engagement with corner picking

- Reduced need for incremental depth passes with full-depth cutting

- Minimized drag from optimized transitional moves

- Enhanced cutting efficiency with dynamically optimized feed rates