WHY CHOOSE PMT?

EXPERT TRAINING:

Learn from our ESPRIT-certified trainers. On-site or virtually. Become an expert.

DEDICATED SUPPORT:

Get ongoing assistance for all your manufacturing challenges. We're here to help you.

CUSTOMIZED IMPLEMENTATION:

Ensure a smooth transition to ESPRIT with our tailored implementation strategies.

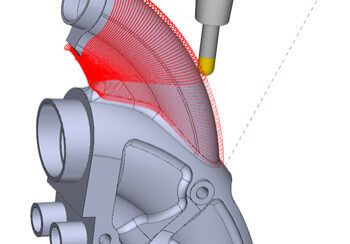

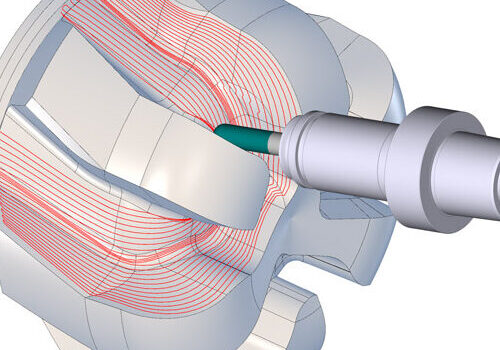

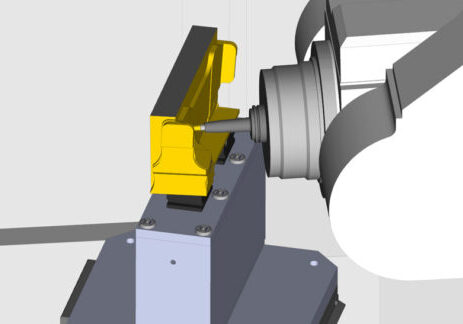

ESPRIT 5-Axis: Precision for All Industries

Unlock the potential of your machining with ESPRIT's FreeForm simultaneous 5-axis machining cycles. You can effortlessly produce intricate tools and components for industries like aerospace, automotive, energy, and medical. Whether you're working on 5-axis, 4+1, or 3+2 applications, you'll benefit from machine-optimized toolpaths that ensure precision and efficiency. Combine these with ESPRIT's comprehensive milling, turning, and inspection capabilities for a seamless, all-in-one part program that meets all your machining and inspection requirements.

- Unlock machine-optimized toolpaths for complex shapes in 5-axis, 4+1, and 3+2 configurations.

- Cater to diverse industries with tools and parts designed for aerospace, automotive, energy, and medical fields.

- Experience Adaptive Machining™ cycles on any CNC machine, ensuring versatility and performance.

- Simplify programming by integrating FreeForm cycles with milling, turning, and inspection in one complete program.

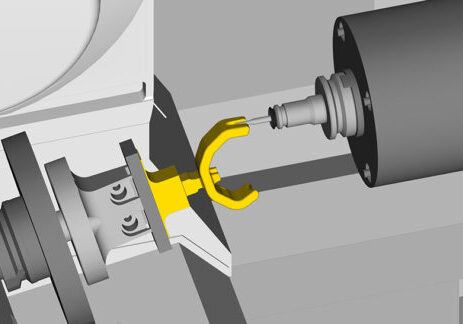

Stock-Aware Toolpath

Machine-Optimized G-Code

Benefit from ESPRIT's machine-optimized G-code, designed for shorter setup and faster cycle times. By optimizing point distribution and code blocks, ESPRIT ensures smooth machine operation and superior surface quality. The tool control center point output enhances machine movement for faster feed rates and higher quality finishes, providing you with a competitive edge.

Key Features:

- Experience faster setup and cycle times with optimized G-code.

- Ensure smooth trajectories around sharp curves for better surface quality.

- Improve machine movement with tool control center point output.

- Adjust for tool wear with 3D tool compensation, enhancing flexibility and precision.

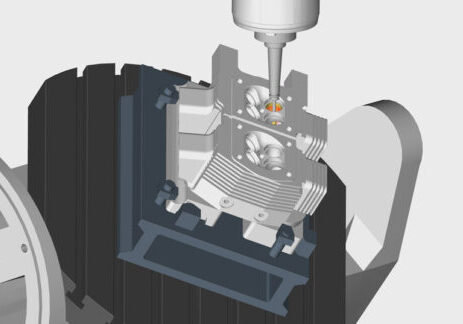

Optimizing the Program

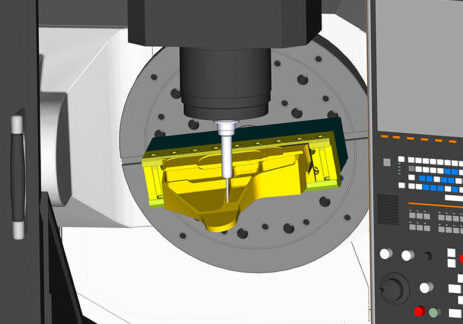

ESPRIT's digital twin technology provides a comprehensive understanding of your CNC machine's environment, streamlining programming and optimizing G-code. With features like the automatic link generator and feed rate optimizer, you can effortlessly navigate complex geometries and improve machining efficiency. ESPRIT's awareness of your machine's capabilities enables precise, efficient, and safe machining operations, significantly enhancing your productivity.

Key Features:

- Simplify programming with automatic linking moves and optimized rotary solutions.

- Improve surface quality and extend tool life with 5-axis feed rate optimization.

- Navigate complex part geometries with ease, reducing cycle times.

- Maximize machining efficiency with a comprehensive understanding of machine kinematics.

Full Machine Simulation

High-Speed Machining