NCSIMUL Essential Training

This structured, step-by-step curriculum is designed to guide you through the essentials of CNC simulation—from software setup to complete multi-process simulations. Master NC-code validation at your own pace and on your own schedule. Your purchase entitles you to unlimited 12 month access

$995.00

Description

Chapter Overview

Chapter 1: Getting Started

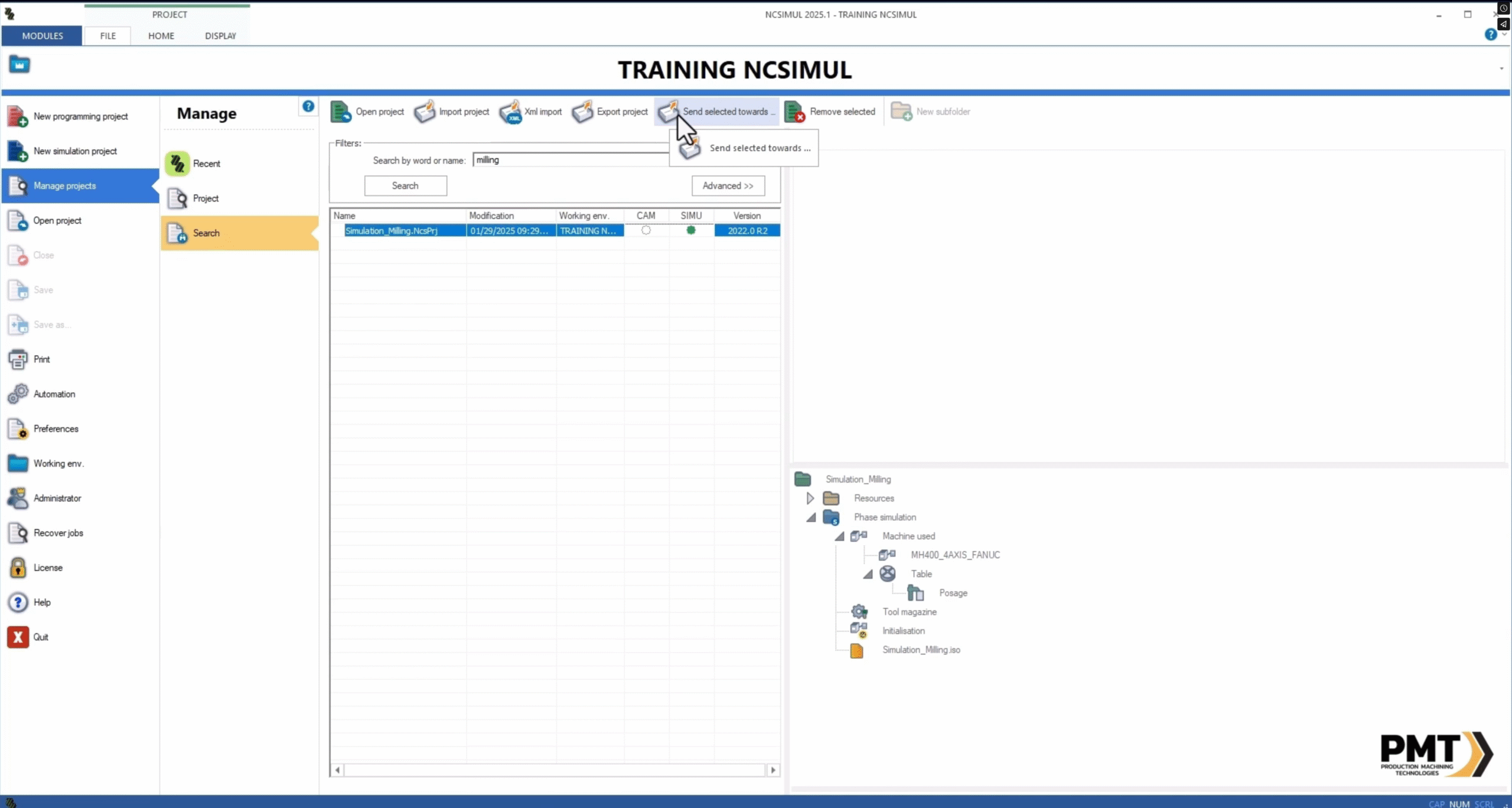

- Launch NCSIMUL Machine and navigate the interface.

- Understand the folder structure and how to modify it.

- Create a custom working environment.

- Explore user preferences and mouse control settings.

- Import/export simulation projects.

- Understand the importance of Admin Mode and training environments.

Chapter 2: Intro to the User Interface

- Walk through the Project tab, Resources section, and Simulation Phases.

- Navigate the Process Edit tab and Machine Axes Movement.

- Use the Setup Editor and define part positioning with imported CAD.

- Learn about Zero Setup and its impact on project configuration.

- Explore the Tool Library and Initialization options.

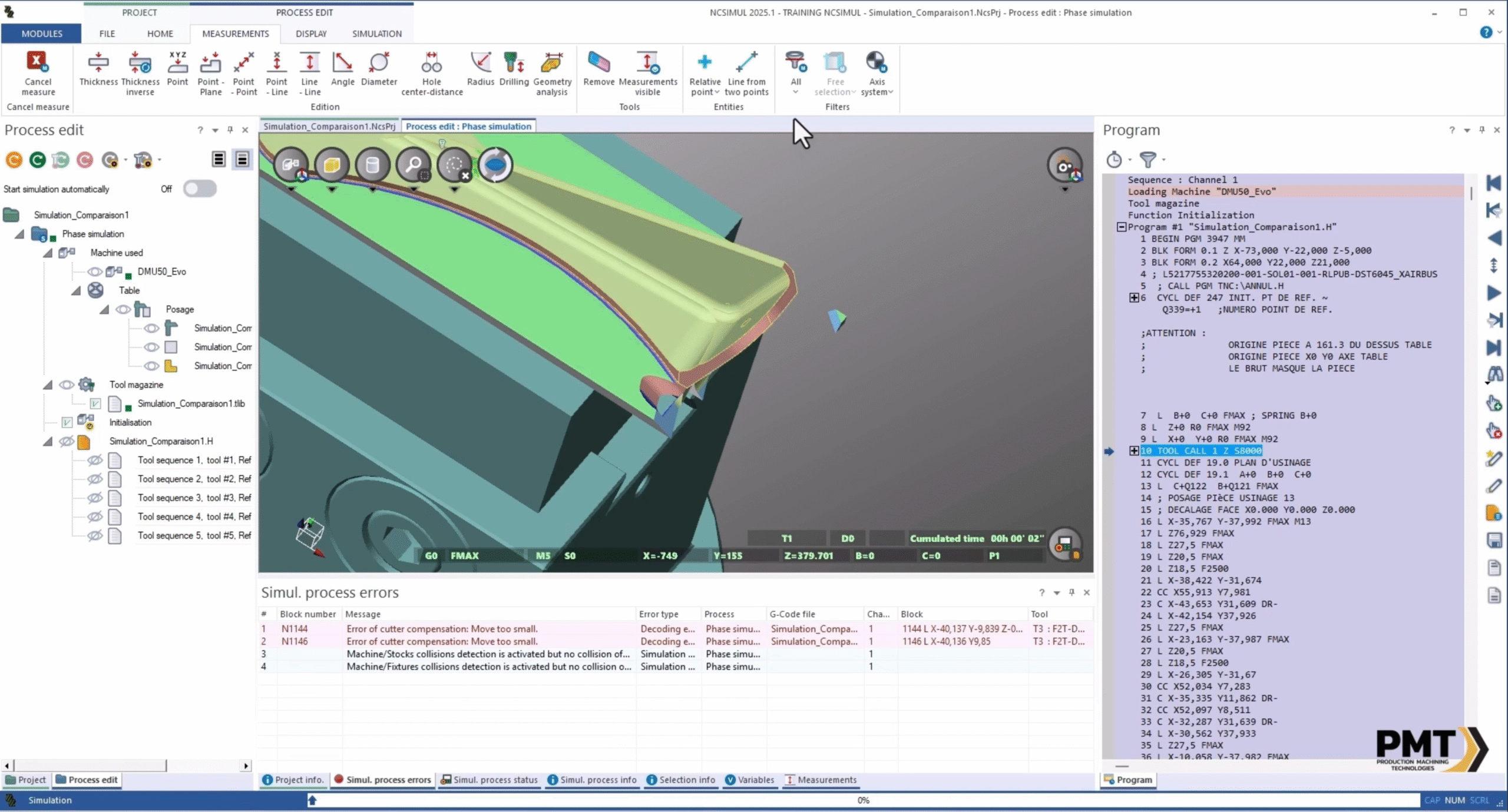

Chapter 3: Understanding NC Program Tools

- Explore options in the NC Program section.

- Use “Simulate Selected Operation” to test specific lines.

- Decode errors with Simul Process Error detection (axis locks, overtravels, etc.).

- Read time, feed, speed, and tool status with Simul Process Status.

- Review complete operation data with Simul Process Info.

- Understand measurements, variables, and selection details.

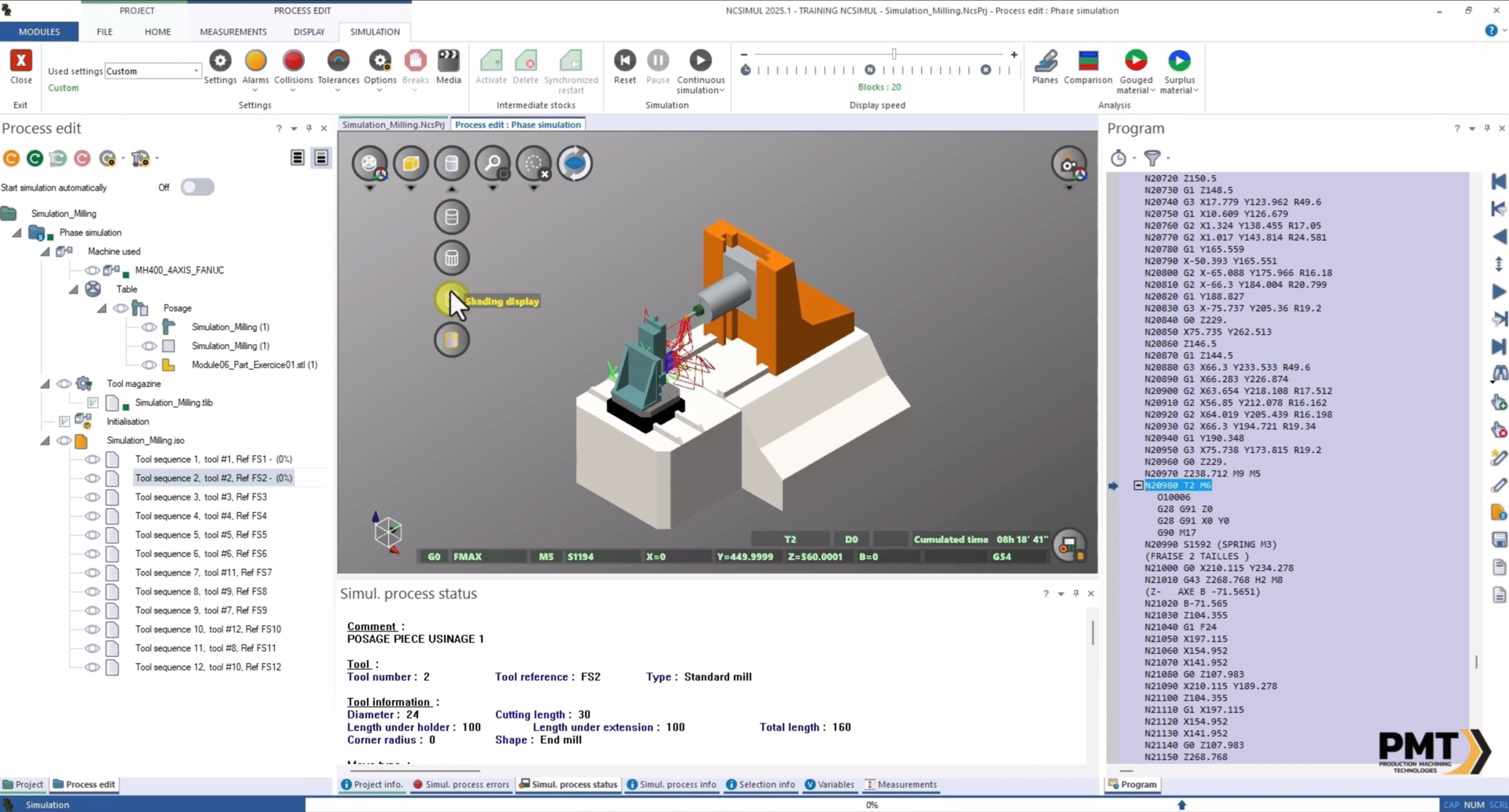

Chapter 4: Mastering the 3D Simulation View

- Switch between Machine View and Table View.

- Adjust orientation: ISO, Top, Front, etc.

- Change display modes: Wireframe, Shaded, and others.

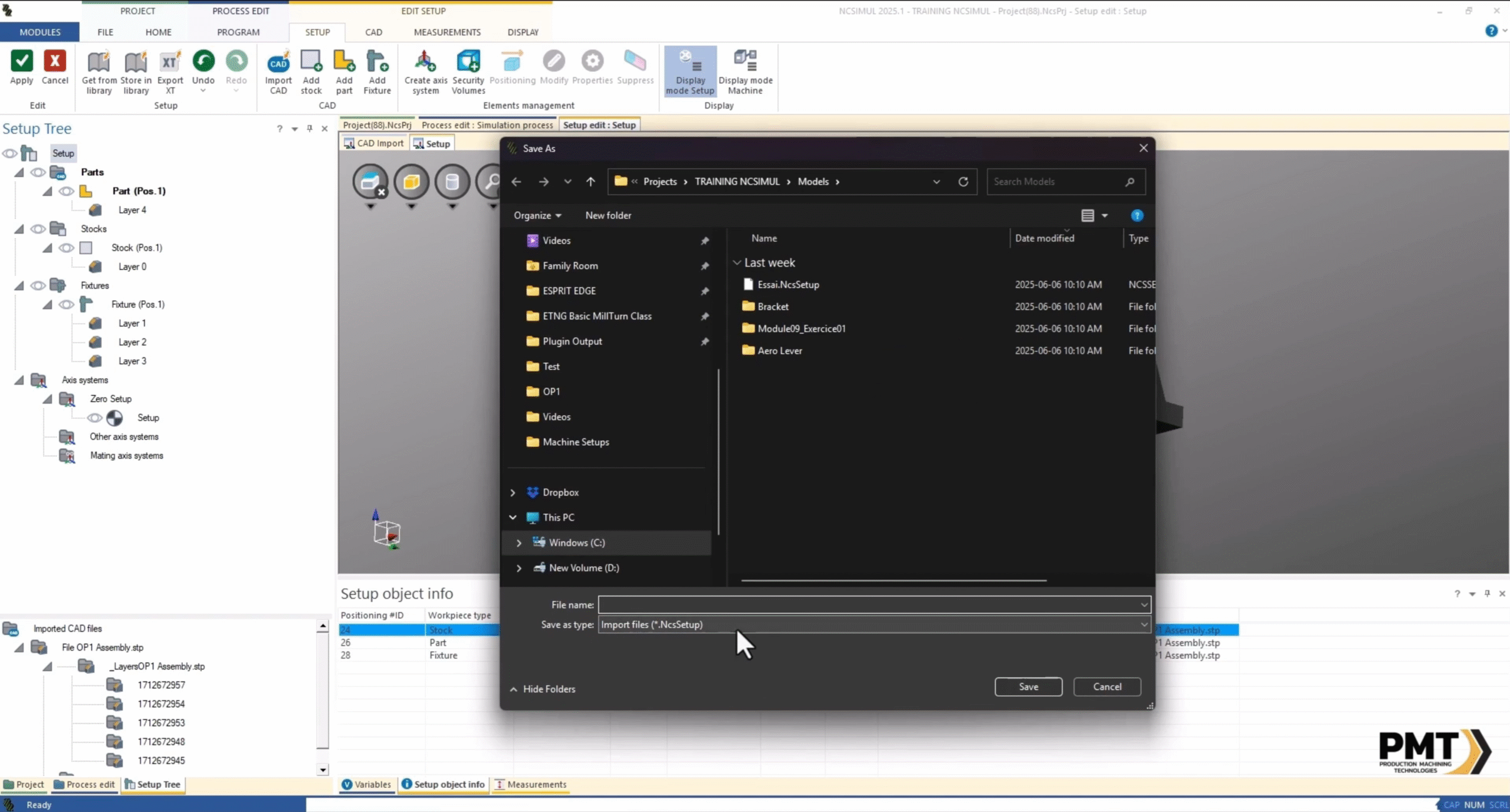

Chapter 5: Creating a New Setup

- Unzip your training files and access all simulation assets.

- Start a new project using OP10.CAT.

- Define Stock, Part, and Fixture using the Setup tab.

- Position the Axis System and set Security Volume parameters.

- Build tool assemblies and import extension/holder models.

- Set compensation values for tool radius and length.

Chapter 6: Single Simulation Process

- Load and configure the MH400 4-Axis FANUC machine.

- Use Zero Setup to define the absolute origin.

- Load the bracket tool library and assign the proper G54 datum.

- Import NC program file mp10.tap.

- Run your first complete simulation.

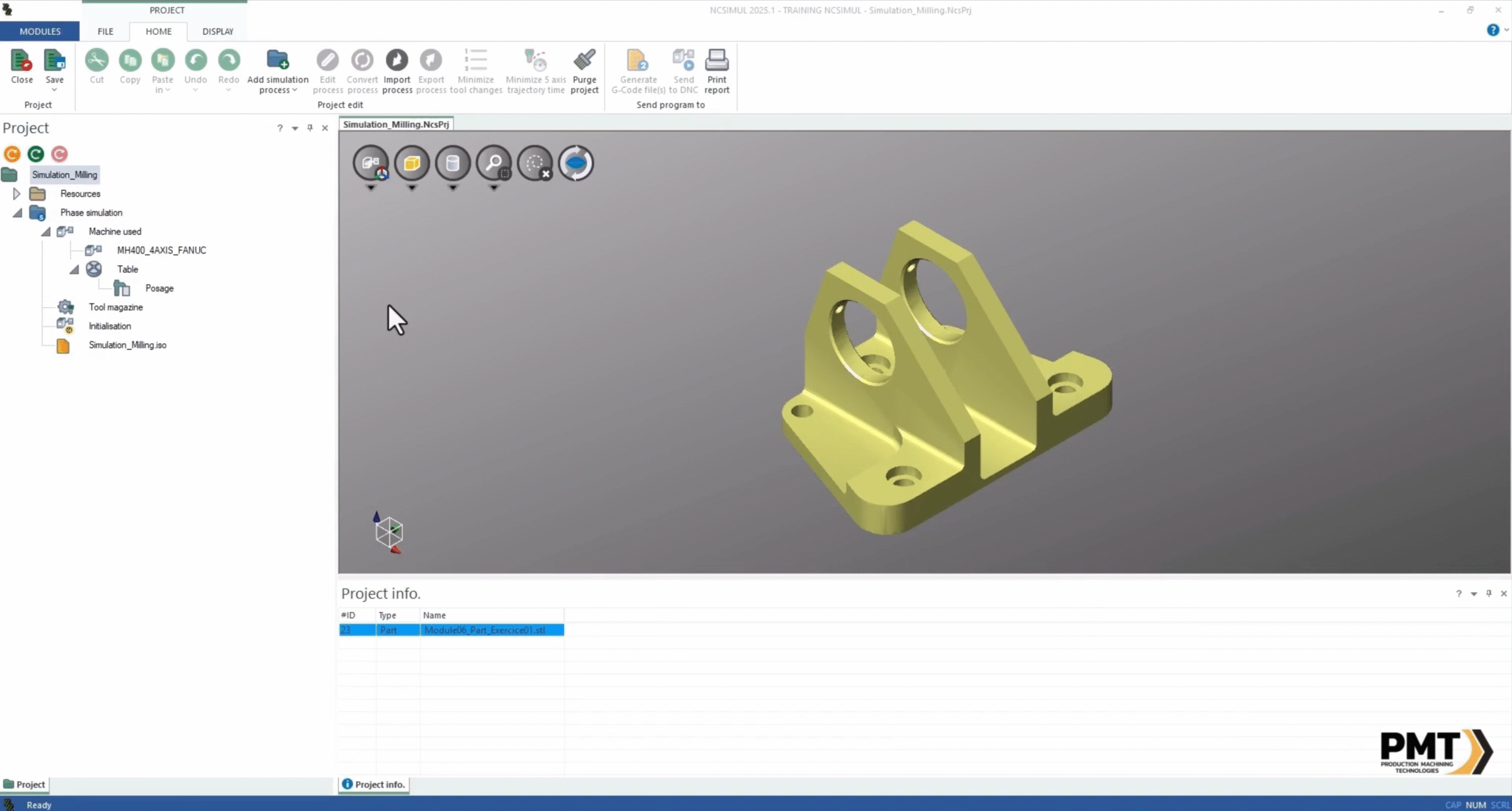

Chapter 7: Multi-Setup Simulation Process

- Add multiple setups using OP20.bracket.

- Assign machines, define new geometry, and import CAD axis.

- Configure absolute zero for each process.

By the End of This Course, You’ll Be Able To:

- Simulate single or multi-step operations with confidence.

- Decode and resolve real NC code errors before reaching the shop floor.

- Build complete setups, assign tools, and analyze simulation results.

- Use NCSIMUL to reduce risk and improve machining productivity.