JITBase & PMT

We are proud to partner with JITBase, a leading solution for optimizing CNC machine performance and operator efficiency. Using real-time machine data, JITBase ensures smarter production planning and improved operator productivity, addressing workforce challenges in manufacturing.

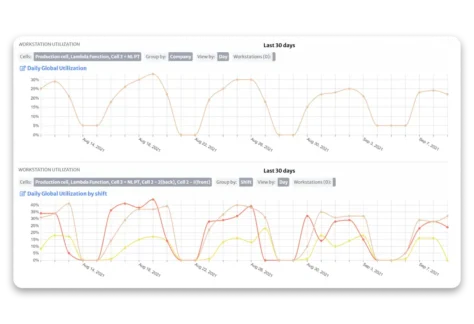

Accurate CNC Data

- Automatic data collection from CNC machines.

- Precise tracking of machine uptime, downtime, and productivity.

- Detailed reporting for identifying bottlenecks and optimizing performance.

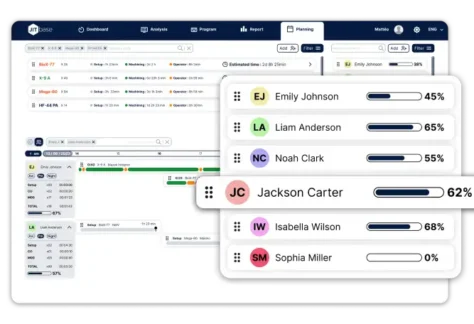

Production Planning

- Aligns operator workload with machine efficiency.

- Predicts potential production delays for proactive management.

- Simplifies workforce coordination with live tracking and scheduling adjustments.

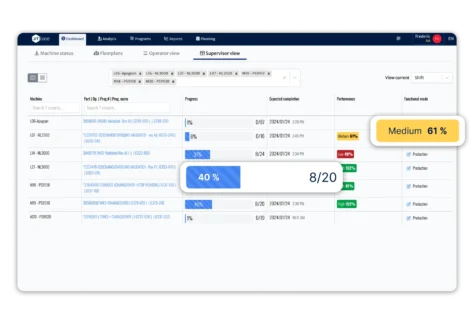

Reduced Machine Downtime

- JITBase uses predictive analytics to anticipate machine failures before they happen.

- By identifying issues early, it minimizes unexpected downtimes and production halts.

- Automated alerts help operators take timely action to ensure smooth operations.