WHY CHOOSE PMT?

EXPERT TRAINING:

Learn from our ESPRIT-certified trainers. On-site or virtually. Become an expert.

DEDICATED SUPPORT:

Get ongoing assistance for all your manufacturing challenges. We're here to help you.

CUSTOMIZED IMPLEMENTATION:

Ensure a smooth transition to ESPRIT with our tailored implementation strategies.

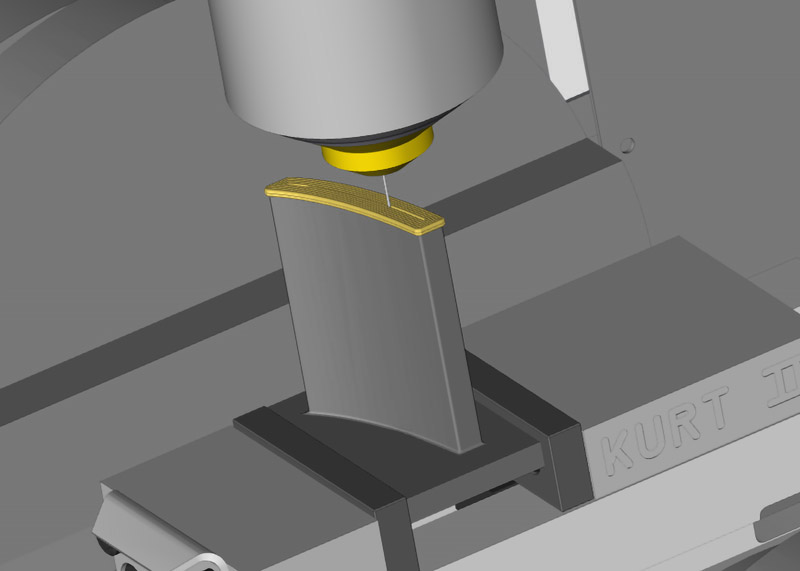

Seamless Integration of Additive Manufacturing

ESPRIT CAM supports additive manufacturing with a system that blends both additive and subtractive processes into one harmonious workflow. Whether you're working with hybrid or dedicated additive machines, this solution is tailored to optimize your production, ensuring a smooth transition between adding and shaping materials. Experience the convenience of having stock-aware cycles and comprehensive simulations at your fingertips, guaranteeing precision in every project.

- Integrated additive and subtractive programming

- Tailored for hybrid and dedicated additive machines

- Optimized stock-aware cycles for efficiency

- Comprehensive simulation for precision assurance

DED 4-Axis

DED 5-Axis

Unlock the full potential of additive manufacturing with our 5-axis DED technology, dynamically tilting your part for optimal material addition. This cycle intelligently calculates simultaneous movements, ensuring precise material deposition and incorporating cooling times when necessary, facilitating a seamless 5-axis building process.

- Dynamic 5-axis movements for superior deposition

- Integrated cooling timing for process optimization

- Enables creation of geometrically complex components

- Facilitates efficient and precise manufacturing processes

Machine-Aware Direct Energy Deposition

Experience unmatched versatility in direct energy deposition with a system that understands your machine as well as you do. From programming to simulation, this workflow is designed for both dedicated and hybrid machines, covering a wide range of manufacturing needs. Enjoy collision-free and time-optimized operations, supported by a digital twin of your machine, ensuring a seamless process from start to finish.

- Adaptable to any CNC machine configuration

- Unified additive and subtractive process programming

- Machine-aware optimization for seamless operations

- Collision-free and time-optimized cycles with full simulation