Posts by George Nacarato

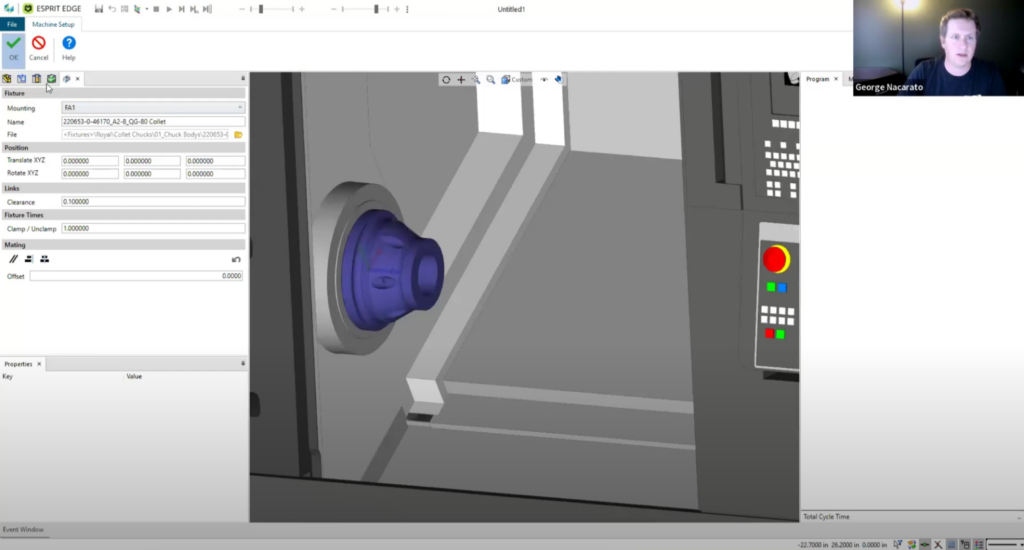

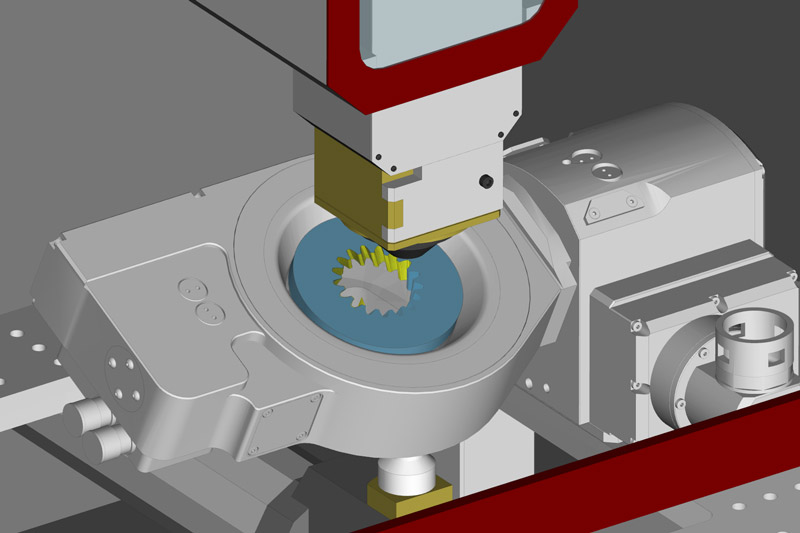

Better Understanding Holders, Fixtures, and Other Machine Components in ESPRIT EDGE

When setting up machine components in ESPRIT EDGE, understanding attachment points and how different components connect is crucial for a successful workflow. Each component type has a specific prefix that helps define its attachment point and purpose. Let’s break this down into manageable sections to better understand the naming conventions and their practical applications. Key…

Read MoreUnderstanding Toolpath Optimization

Toolpath optimization is a cornerstone of efficient CNC machining operations. By refining the paths that cutting tools follow, you can significantly reduce machining time, improve product quality, and optimize resource use. Mastering effective toolpath strategies leads to better cost efficiency, enhanced precision, and increased productivity. Advanced computer-aided manufacturing (CAM) techniques play a key role in…

Read MoreAnswered: What is G-Code?

G-Code, is the programming language that drives CNC machinery. It is the code that drives the movement of machines and enables simulations to take place. Keep reading to learn more about how G-Code continues to revolutionize precision machining and manufacturing! What is G-Code? G Codes are the commands that tell CNC machines how to…

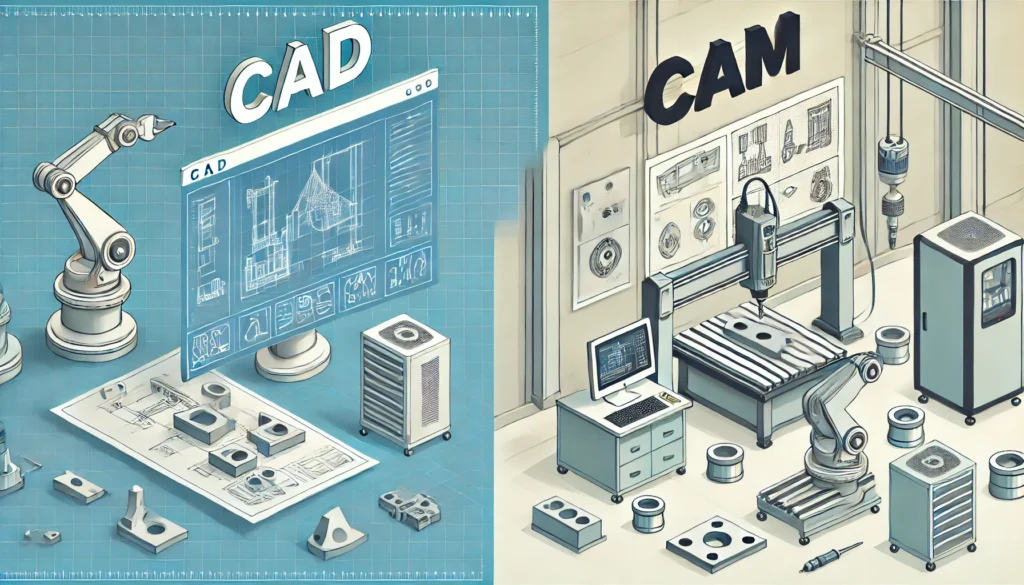

Read MoreCAD and CAM: Key Differences Explained

Understanding the difference between CAD and CAM is crucial for professionals navigating the fields of engineering, architecture, and design. While these technologies often work in tandem, their roles and impacts on the workflow are distinctively different. This page aims to clarify these differences through a detailed exploration of their core functionalities, practical applications, and individual…

Read MoreThe Essentials of Computer-Aided Manufacturing (CAM)

In today’s rapidly advancing technological landscape, the integration of computer systems into manufacturing processes has revolutionized the way industries operate. At the forefront of this transformation is Computer-Aided Manufacturing, commonly referred to as CAM. Whether you’re an industry professional, a student, or simply curious about this groundbreaking technology, understanding CAM is crucial for grasping its…

Read MoreThe History & Evolution of CAM Software

Computer-Aided Manufacturing (CAM) software, sometimes called “computer aided machining,” has revolutionized the way industries approach manufacturing processes. By enabling the precise control of machine tools and streamlining production workflows, CAM software has become an indispensable asset in modern manufacturing. From its humble beginnings in the mid-20th century to the sophisticated, automated systems we see today,…

Read MoreWhat is Wire EDM?

Wire Electrical Discharge Machining (Wire EDM) stands as a cornerstone of precision manufacturing. It offers unmatched capabilities in the cutting of hard materials with intricate designs. Paired with Computer-Aided Machining (CAM) Software, wire EDM manufacturing offers some of the most accurate cutting capabilities in the world. Understanding Wire EDM Technology Wire Electrical Discharge Machining…

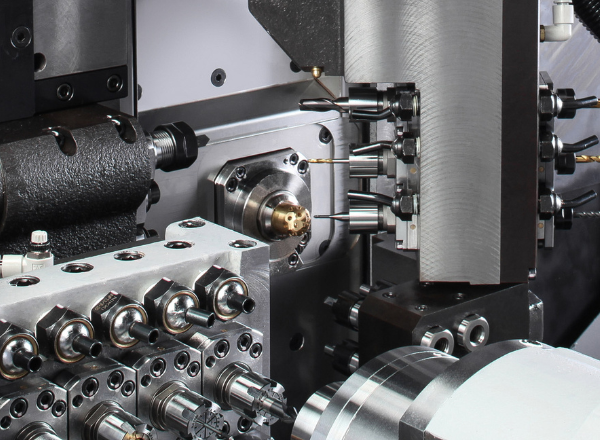

Read MoreOptimizing Your Swiss Turning Operations

Swiss turning technology is at the forefront of precision manufacturing, essential for producing complex components with stringent tolerance requirements. This technology is particularly indispensable in industries like medical, aerospace, and high-precision engineering, where the slightest deviation in part dimensions could lead to significant issues. In this blog, we’ll explore a comprehensive suite of strategies designed…

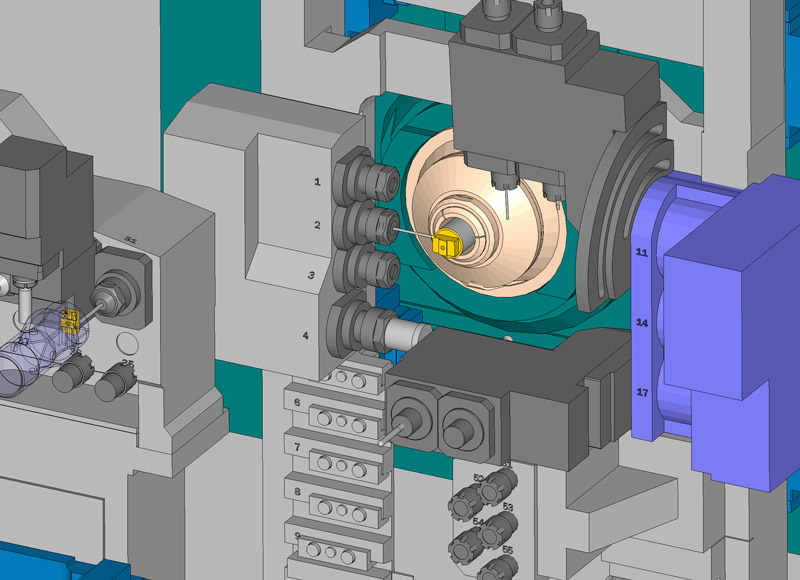

Read MoreWhat is Swiss Machining?

Precision manufacturing as evolved significantly over the years, introducing technologies that allow for greater efficiency and exactness. Among these technologies, Swiss machining stands out for its ability to produce extremely precise components. This blog post will explore the basics of Swiss machining, its unique advantages, and its diverse applications across various industries. What is…

Read More